Applications of High-Speed Cameras: From Industrial Testing to Cinematic Storytelling...

Read MoreEnter your details below to download the product catalogue.

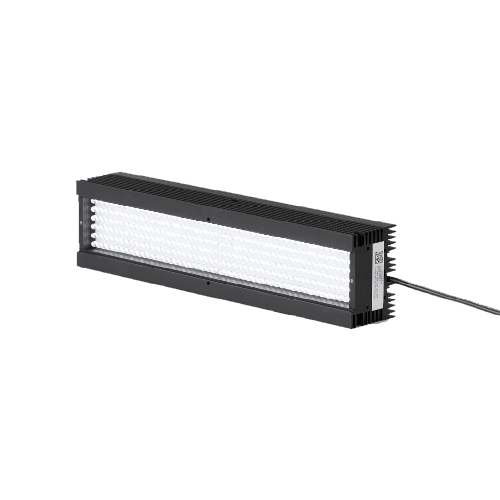

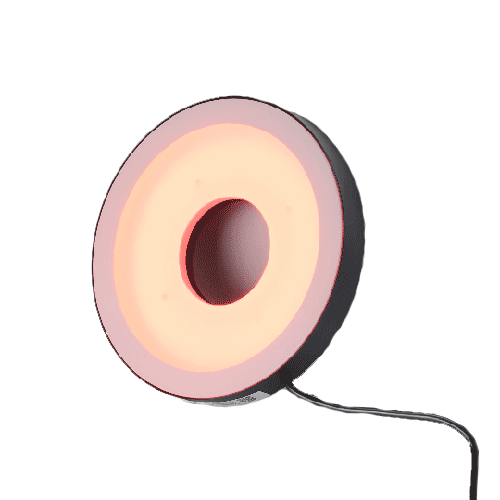

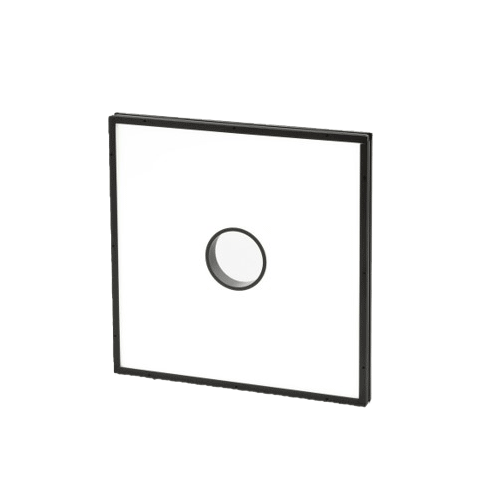

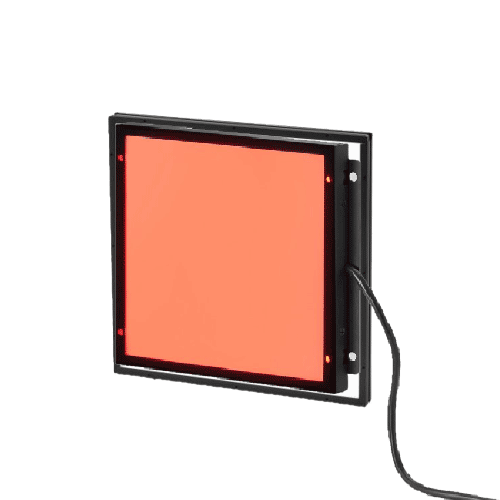

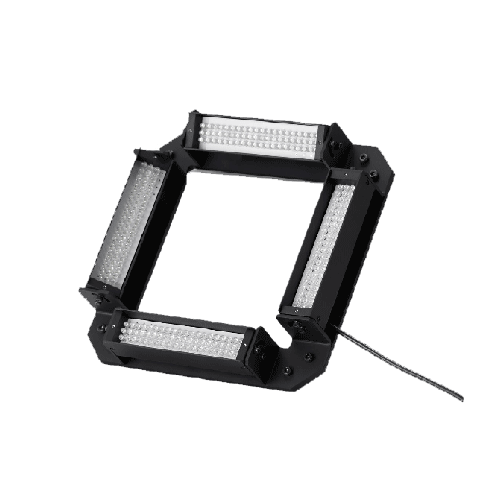

Discover superior-quality machine vision lighting solutions to achieve clear, precise, and consistent imaging in automated inspections and industrial applications.

Minimize errors in detection and analysis by choosing the right machine vision lighting that does not compromise image quality. Automated systems require accurate and reliable image capturing to reach the desired results. Machine vision lighting provides uniform and controlled illumination that can minimize shadows, enhance contrast, and give attention to the finest detail, thus helping to reach precision in inspection and productivity in the industry.

Choosing the right machine vision lighting starts with identifying the application's requirements, characteristics, and, most importantly, environmental conditions. For optimal image clarity and contrast, consider light intensity and wavelength. Selecting the light type, angle, and position too is crucial as it reduces shadows to highlight the relevant areas to reach the desired outcome.

The light selection starts by creating the contrast for what you want to see in the object. The lighting should be able to create uniform brightness across the subject without causing reflections or shadows.

Machine Vision lights are designed to operate in Continuous mode and Strobe mode. Strobing can be from the camera or external power source. This virtually eliminates blur and noise caused by a vibrating conveyor or subject in high speed motion.

The lighting techniques vary based on the application. Surface inspection, engraved OCR, and Measurement are the typical examples where different types of lighting are used. Dark field and Bright field are other lighting techniques used.

The Size, Physical Complexity, Colour, Specularity of the subject makes the light selection difficult. Different types of lighting and multiple lighting configurations need to be utilized to tackle such challenges and get the perfect imaging.

Reflections & Shadows are the biggest challenges faced by the customers. Polarization, Angle of illumination and lighting configurations can fully avoid the reflections and shadows, at the same time highlighting the features being inspected.

| Customers often make the mistake of considering the same size of light based on the area of interest. Lighting area is not proportional to the size of the light and will vary with the position and WD of the light and the subject. |

See our valuable OEM partners who are some of the top names in the industry

Learn how machine vision and AI computer vision transformed obsolete manual processes and revamped existing automation.

Applications of High-Speed Cameras: From Industrial Testing to Cinematic Storytelling...

Read MoreWhat Are High Speed Cameras: A Comprehensive Guide If you...

Read MoreSWIR vs MWIR vs LWIR Cameras: Tech Specs Comparison &...

Read MoreEnter your details below to download the product catalogue.