How to Select the Right LWIR Camera for Surveillance Applications

Long-Wave Infrared (LWIR) cameras have become essential in modern surveillance because they detect heat instead of relying on visible light. Operating in the 8 to 14 µm range, they work in complete darkness and through challenging conditions such as fog, haze, smoke, and glare. Their passive operation makes them dependable for round-the-clock monitoring across industrial sites, borders, perimeters, and critical infrastructure. Selecting the right LWIR camera requires understanding several technical parameters, especially when the application demands reliable detection and identification.

Understanding LWIR Technology

LWIR cameras use uncooled microbolometer sensors that measure temperature differences in a scene and convert them into thermal images. Since all objects emit thermal radiation, LWIR cameras function independently of lighting conditions. This advantage makes them ideal for environments where visible cameras fail, such as at night, during storms, or in visually obstructed locations. LWIR imaging supports consistent surveillance across day and night cycles without reliance on artificial illumination.

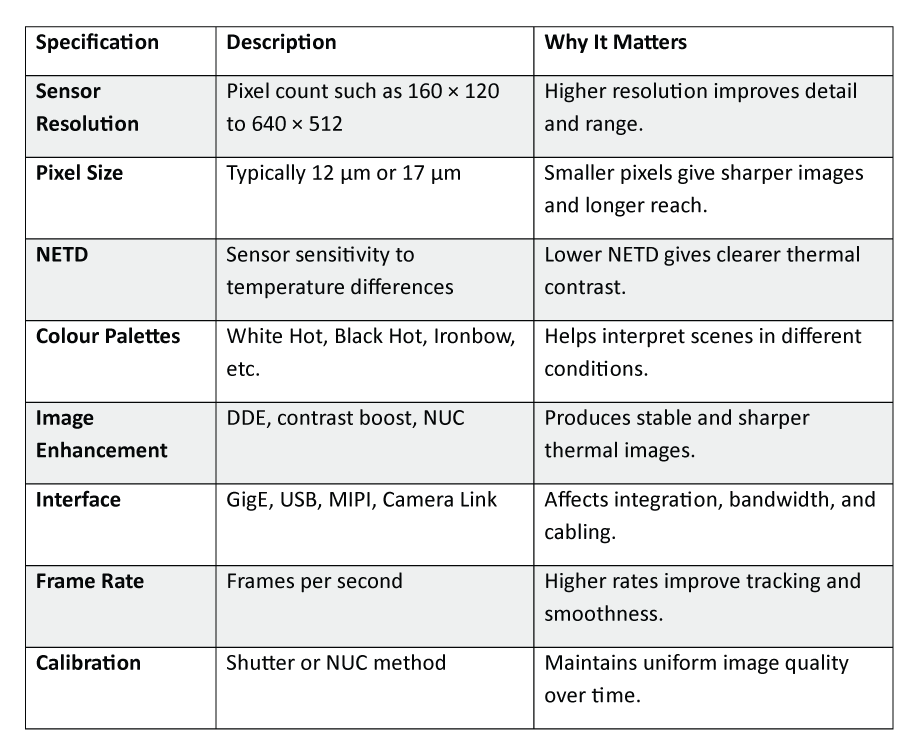

Evaluating Key LWIR Camera Specifications

Selecting an LWIR camera requires evaluating its sensor attributes, sensitivity, image processing capabilities, and output interface. Each factor directly affects performance, clarity, and the camera’s ability to detect intrusions or anomalies.

Sensor Resolution

Resolution defines the level of detail an LWIR camera can capture. Entry-level models typically range from 160 × 120 to 320 × 256, while advanced systems offer 640 × 512 and above. At the highest end, resolutions like 1280 × 1024, which we offer, deliver exceptional long-range clarity and superior image quality for both operators and AI analytics. A 640 × 512 camera is often considered the professional standard, but 1280 × 1024 takes detection accuracy and detail to an even higher level, making it ideal for demanding surveillance, industrial, and research environments.

Pixel Size

Pixel size, measured in micrometers, influences image sharpness, detection range, and field of view. Common pixel sizes include 17 µm and 12 µm. Smaller pixels capture more detailed spatial information, enabling similar detection distances with shorter lenses, resulting in a compact system with high clarity. Larger pixel sizes, however, provide a wider angle of view, while smaller pixels allow the camera to see farther, extending long-range detection performance.

Because very small pixels may collect less thermal energy, it’s important to balance pixel size with the right lens. For most surveillance applications, a 12 µm pixel size offers excellent detail without compromising sensitivity.

NETD (Noise Equivalent Temperature Difference)

NETD measures how well the camera distinguishes even the smallest temperature differences in a scene. A lower NETD value indicates higher sensitivity. Cameras with NETD levels below 40 mK deliver clearer thermal separation, sharper outlines, and more reliable performance in low-contrast environments. This is especially valuable in warm conditions where object and background temperatures may be very close.

We offer both <50 mK and <30 mK NETD options, ensuring consistent visibility and dependable event detection even at long distances or in challenging low-contrast scenes. Choosing a low-NETD camera enhances overall image clarity and improves detection accuracy across all surveillance scenarios.

Colour Palettes and Image Processing

LWIR cameras represent thermal data through colour palettes such as White Hot, Black Hot, Ironbow, and Rainbow. White Hot and Black Hot are preferred for security because they provide simple and high-contrast displays that make people and vehicles easy to spot. More vivid palettes such as Ironbow help highlight subtle temperature gradients in specialized use cases.

Modern LWIR cameras include image enhancement features that optimize clarity. Digital detail enhancement, dynamic contrast adjustment, and non-uniformity correction help produce stable and sharp thermal images. These features become essential when monitoring large areas, low-contrast environments, or scenes with minimal temperature variation.

Interface and Connectivity

The interface determines how the camera integrates with the rest of the surveillance system. GigE Vision is widely used for installations that require long cable runs and stable high-bandwidth video. USB 3.0 offers fast data transfer for embedded or portable systems. Some installations use MIPI or Camera Link for industrial or robotic applications. When choosing an interface, consider compatibility with the existing VMS, the distance to the control room, and power delivery options. GigE with PoE is preferable for many fixed installations due to its simplicity and reliability.

Lens Selection and Why It Matters Most

The lens is one of the most critical components in an LWIR system because it determines the field of view, detection distance, and overall image clarity. Even the best sensor cannot compensate for an unsuitable lens, making thoughtful lens selection central to surveillance performance.

Focal Length and Field of View (FOV)

Focal length determines how far the camera can see and how wide the scene appears. Shorter focal lengths provide wider coverage and are suitable for general monitoring of open areas, building entrances, and vehicle zones. Longer focal lengths narrow the field of view and allow the camera to detect people or vehicles at extended distances, making them ideal for border security and long perimeter lines.

Choosing the correct focal length requires understanding how far the monitored area is from the camera mount and whether the priority is broad situational awareness or long-range detection.

Angle of View (AOV)

Angle of View indicates how much of the horizontal and vertical scene the camera captures. A wide AOV is suitable for covering open spaces or areas with high movement. A narrower AOV focuses attention on distant targets, improving detail and reducing distractions. When planning large surveillance systems, combining cameras with varying AOVs ensures both wide coverage and long-range visibility.

DRI (Detection, Recognition, Identification)

Detection, Recognition, and Identification (DRI) distances are key performance indicators that define how effectively a thermal camera can classify objects at various ranges. While Johnson’s Criteria is one of the most commonly referenced methods, DRI can be calculated using multiple models, each applying different pixel thresholds.

At its core, DRI is determined by the number of pixels that cover the target:

- Detection requires enough pixels to confirm that an object is present.

- Recognition requires a higher pixel count to distinguish whether it is a human, animal, or vehicle.

- Identification needs the highest pixel density to reveal finer details such as clothing, equipment, or object type.

DRI performance is influenced by sensor resolution, pixel size, and lens focal length. Higher-resolution sensors and longer focal length lenses extend detection and identification ranges, while shorter lenses limit performance to closer distances. Evaluating DRI ensures the chosen configuration meets the intended surveillance or monitoring requirements.

Lens Material and Coatings

LWIR lenses use materials such as Germanium or Chalcogenide that transmit infrared wavelengths effectively. Germanium offers excellent clarity and performance but is more expensive. Chalcogenide provides a cost-effective alternative for many surveillance setups.

Lens coatings improve transmission efficiency and protect against scratches, humidity, and environmental stress. Hard carbon coatings are common in outdoor lenses because they enhance durability and ensure consistent performance in harsh weather.

Environmental and Mechanical Considerations

LWIR cameras deployed outdoors must withstand varying temperatures, moisture, dust, and impact. An appropriate IP rating such as IP66 or IP67 ensures resistance to water and debris. For industrial or mobile applications, shock and vibration tolerance is equally important. Thermal cameras also rely on internal calibration systems that maintain image uniformity. Cameras with efficient non-uniformity correction ensure long-term stability and performance during continuous operation.

System Integration and Analytics Compatibility

Modern surveillance relies heavily on seamless integration with video management systems and analytics platforms. LWIR cameras should support common communication protocols, SDKs, and, when required, ONVIF standards to ensure smooth interoperability. Compatibility with AI-based detection, motion tracking, and thermal analytics is essential for turning thermal data into actionable insights rather than mere imagery. Power considerations such as PoE also simplify cabling and installation.

In modern applications, especially in drones and UAV payloads, LWIR camera compatibility with Linux systems and ARM-based platforms like NVIDIA Jetson has become critical. This ensures efficient processing, low-latency data handling, and easy integration into compact, weight-optimized airborne systems.

Conclusion

Selecting the right LWIR camera for surveillance requires evaluating sensor performance, pixel architecture, NETD sensitivity, processing capabilities, interface compatibility, and environmental durability. Lens selection, including focal length, angle of view, and DRI performance, plays one of the most significant roles in real-world effectiveness. When these elements are properly aligned with application needs, LWIR cameras deliver dependable performance, long-range detection, and consistent imaging across all lighting and weather conditions. A well-chosen LWIR system enhances situational awareness and ensures robust security coverage for demanding surveillance environments.