SWIR vs MWIR vs LWIR Cameras: Tech Specs Comparison & Applications

Infrared imaging is now an essential part of modern machine vision, industrial monitoring, defence systems, and surveillance. But while most people refer to “thermal cameras” broadly, the reality is that infrared imaging spans multiple wavelength bands, each with different behaviours, advantages, and limitations.

The three most widely used infrared categories are SWIR (Short-Wave Infrared), MWIR (Mid-Wave Infrared) and LWIR (Long-Wave Infrared). Understanding how these technologies differ can help you make the right choice for your project, whether it’s inspection, temperature measurement, environmental monitoring or security.

Understanding the Infrared Spectrum

Infrared light sits just beyond the visible spectrum, but it covers several atmospheric transmission windows. These windows influence how deeply each wavelength can penetrate fog, dust, glass, silicon or moisture.

- SWIR: 0.9 to 1.7 μm (sometimes up to 2.5 μm)

- MWIR: 3 to 5 μm

- LWIR: 8 to 14 μm

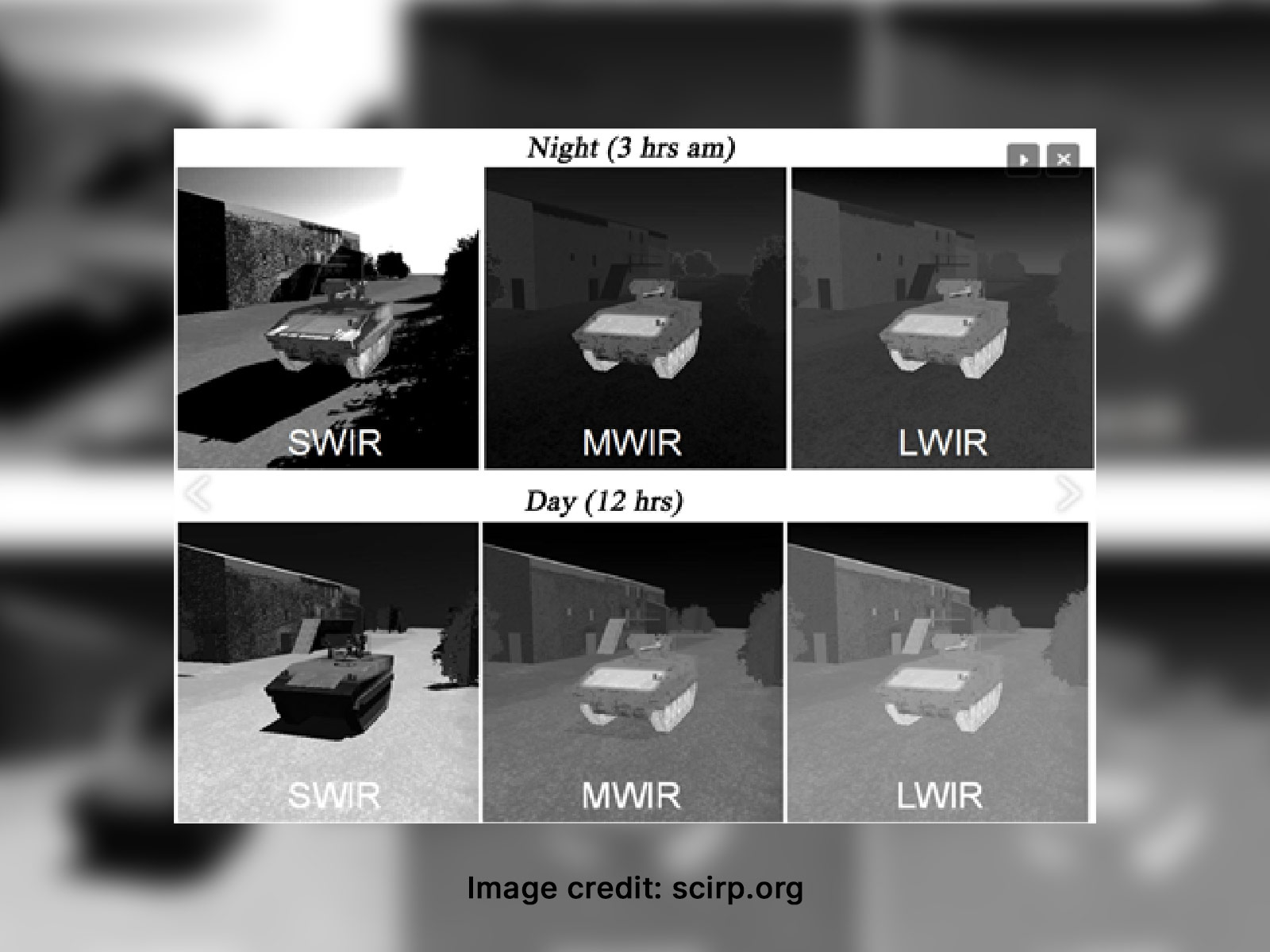

Each region behaves differently. SWIR relies on reflective imaging similar to visible light. MWIR and LWIR detect emitted heat, but MWIR is more sensitive to fast temperature changes, while LWIR excels in general thermal detection.

How Each Camera Type Works

SWIR Cameras

SWIR imaging behaves more like visible imaging than thermal. It captures reflected light, allowing it to maintain sharp contrast in both daylight and low-light scenarios. Because SWIR sees through atmospheric haze far better than visible light, it is extremely valuable for applications where clarity matters in difficult lighting. It can also see through fog and smoke, making it suitable for extreme weather conditions that block visibility.

Most SWIR cameras use InGaAs sensors and do not require cooling. This keeps them relatively compact, simpler to integrate and more durable. They also use standard glass optics, which makes lens availability broader and less expensive compared to MWIR and LWIR systems.

MWIR Cameras

MWIR cameras detect thermal radiation that mid-temperature objects naturally emit. They are the preferred choice when temperature accuracy and dynamic thermal behavior matter.

Unlike SWIR or LWIR, MWIR sensors usually require cryogenic cooling such as a Stirling cooler. This dramatically reduces noise and enhances sensitivity. This cooling system is what gives MWIR cameras their excellent thermal precision, but it also makes them more complex and costly.

MWIR systems are commonly used for scientific research, gas detection and defence applications where high-speed temperature changes must be tracked with accuracy.

LWIR Cameras

LWIR covers the longest thermal wavelengths and is what most people refer to when they say “thermal camera.” These cameras detect the low-energy heat signatures coming from humans, buildings, electronics and the environment.

LWIR systems rely on microbolometer sensors, typically VOx or amorphous silicon, which operate without cooling. This makes LWIR the most affordable and widely deployed thermal imaging option.

Their greatest strength is the ability to capture reliable heat signatures even in fog, smoke or total darkness. However, LWIR cannot see through glass, so special optics like germanium are required.

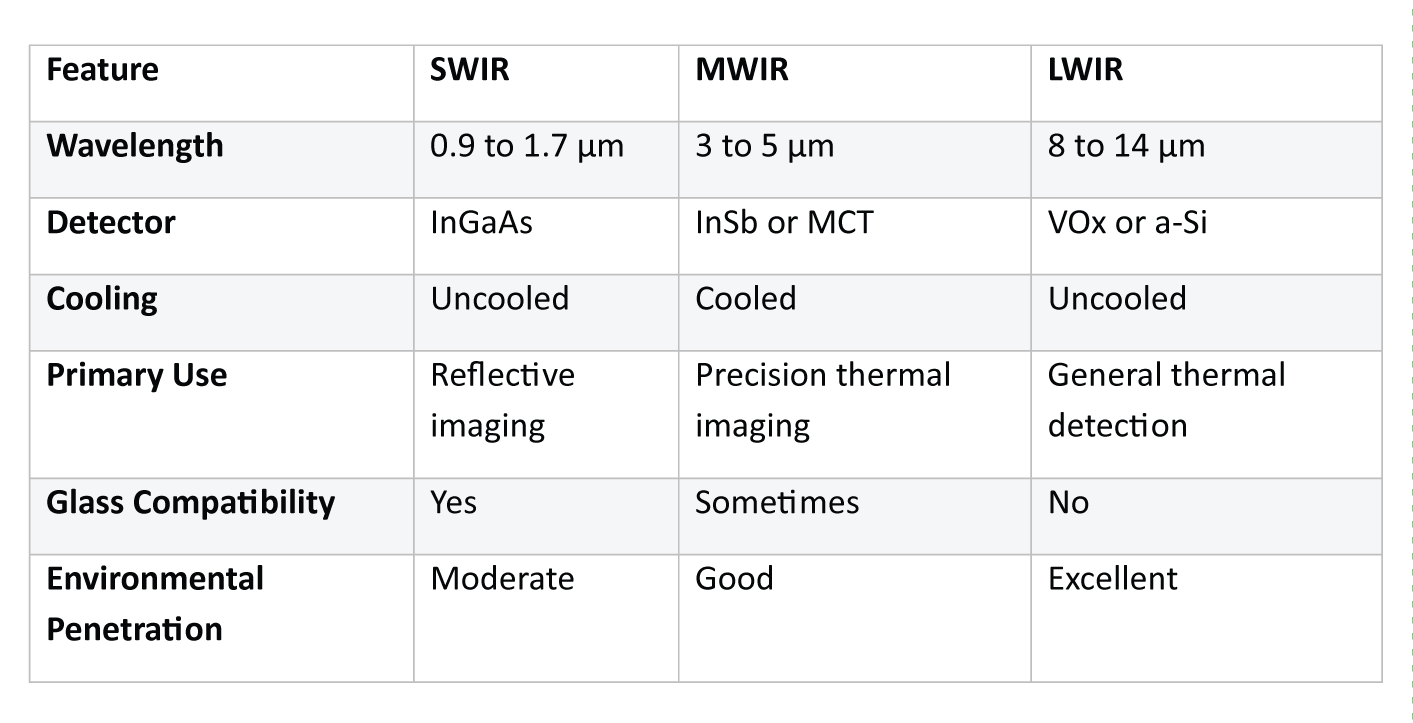

Technical Comparison at a Glance

While each infrared band has unique advantages, the differences become clearer when you compare them side by side.

This shows why there is no universally best infrared band, only the best match for a specific task.

Imaging Performance Differences

Temperature Accuracy

MWIR is the clear leader in applications where temperature must be measured precisely. Its cooled detectors allow extremely low noise levels and fast response times.

LWIR provides good thermal contrast but is not designed for scientific grade measurements. SWIR is not typically used for temperature measurement because it is not based on heat emission.

Detail and Clarity

SWIR stands out for its ability to capture fine details in low light, smoke haze or bright sunlight. Industries that rely on reflective properties, like semiconductor inspection, prefer SWIR for this reason.

MWIR provides excellent clarity but depends heavily on the cooling system for performance consistency. LWIR images tend to be softer due to longer wavelengths, but their thermal contrast is unmatched for detecting heat signatures.

Performance in Harsh Environments

LWIR cameras are the strongest performers in fog, light smoke, dust and low visibility outdoor conditions. MWIR also performs well in reduced visibility but slightly less effectively than LWIR. SWIR handles haze better than visible cameras but is not suitable for dense smoke or fog.

Where These Cameras Are Used

SWIR Applications

SWIR cameras are used extensively in environments where material properties shift under short-wave infrared or where visible cameras fail. Key applications include:

- Semiconductor wafer inspection

- Food sorting and moisture detection

- Laser profiling and alignment

- Silicon and glass component inspection

- Agricultural plant health monitoring

- Surveillance with active IR illumination

MWIR Applications

MWIR excels in temperature sensitive environments and scenarios involving fast thermal changes. Typical use cases include:

- Combustion analysis and high-speed thermal events

- Gas leak detection

- Furnace and kiln monitoring

- Missile tracking and defence systems

- Scientific thermal research

- Predictive maintenance in high-temperature settings

LWIR Applications

LWIR is the most common type of IR imaging due to its affordability and versatility. You will find LWIR cameras in a wide range of commercial and safety-critical scenarios:

- Perimeter and security surveillance

- Search and rescue operations

- Fire detection and firefighting support

- Automotive night vision

- Industrial maintenance

- Building insulation and HVAC testing

Cost, Compatibility and Integration Factors

Cost varies significantly between the three bands, with MWIR being the most expensive because of cooling technology. SWIR sits in the middle, influenced by InGaAs sensor cost. LWIR is generally the most affordable, especially for large-scale deployments.

Beyond cost, integration considerations matter as well:

- Optics: SWIR uses standard glass lenses, whereas MWIR and LWIR require germanium or other specialty materials such as chalcogenide.

- Platform compatibility: Modern IR cameras must support Linux, ARM-based systems, AI analytics and VMS platforms.

- Power and connectivity: Uncooled SWIR and LWIR cameras often support PoE, simplifying installation.

How to Choose the Right Camera

Choose SWIR if you need:

- High-contrast imaging in low light or haze

- Material inspection such as silicon or glass

- Reflective imaging rather than thermal imaging

Choose MWIR if you need:

- Accurate temperature measurement

- High-speed thermal event tracking

- Scientific or defence-grade performance

Choose LWIR if you need:

- General thermal detection

- Surveillance, safety or automotive night vision

- Cost-effective uncooled thermal imaging

Conclusion

SWIR, MWIR and LWIR cameras each offer unique strengths shaped by the physics of infrared light. SWIR is ideal for reflective imaging and precision inspection. MWIR delivers unmatched temperature accuracy. LWIR is the most versatile and widely used thermal band.

Choosing between them is about matching the right wavelength to the right application. With a clear understanding of the technical differences and performance characteristics, you can select the ideal infrared camera for your surveillance, industrial or machine vision needs.