AI in Machine Vision: How It Is Transforming Industrial Vision Systems

Machine vision, the technology enabling machines to interpret and act on visual data, has long been a cornerstone of industrial automation. Traditionally reliant on rule-based algorithms, machine vision systems were limited in their ability to handle complex or variable tasks. The integration of Artificial Intelligence (AI), particularly machine learning and deep learning, is now pushing the boundaries of what machine vision can achieve. This blog explores how AI is revolutionizing machine vision across industries.

What Is Machine Vision?

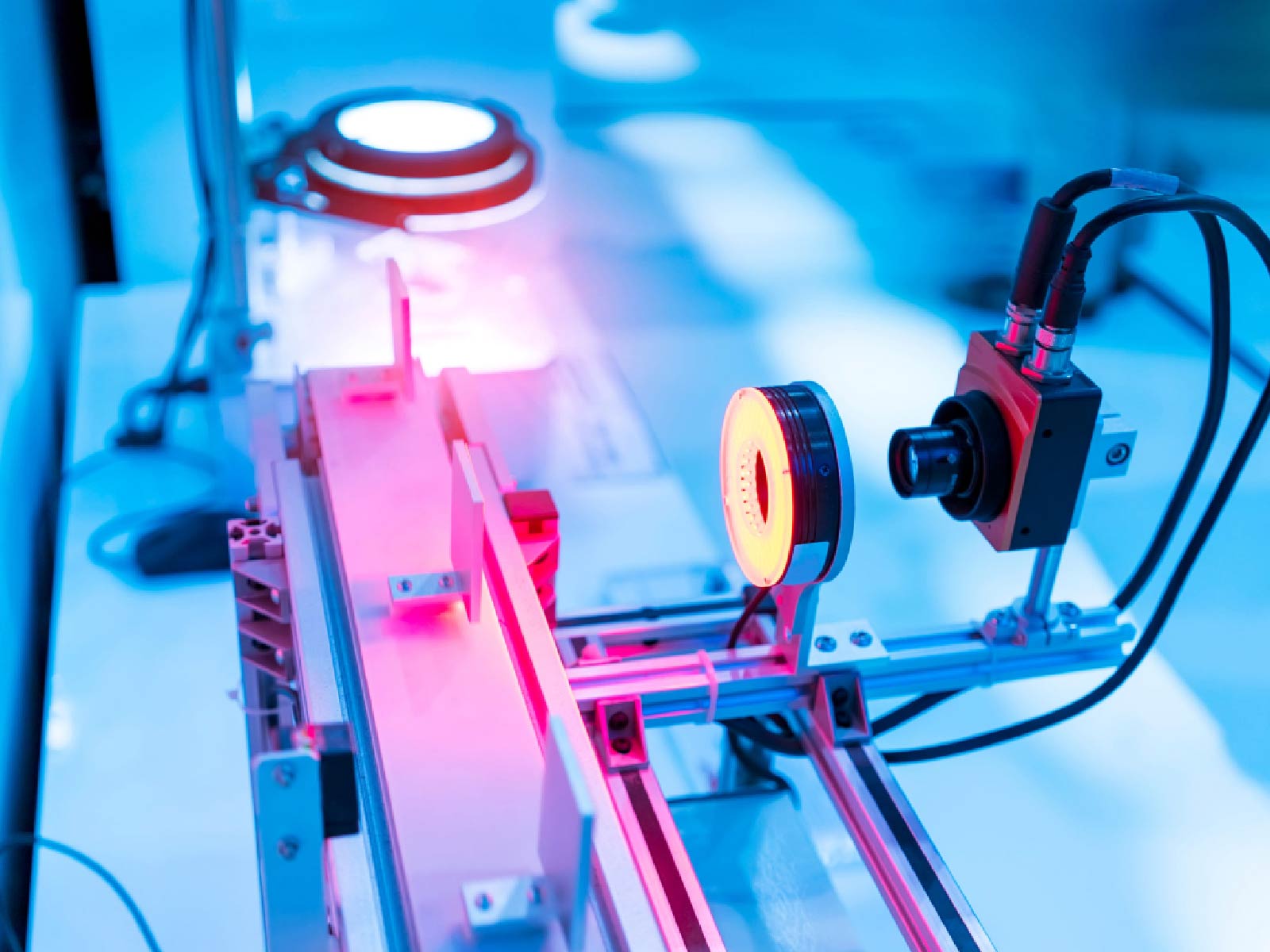

Machine vision involves the use of cameras, lighting, sensors, and software to capture and analyze visual information. In industrial settings, it’s used for inspection, measurement, object recognition, and robot guidance. Traditional systems function well in controlled environments but struggle with variations, anomalies, or complex decision-making tasks.

The Evolution: From Rule-Based to AI-Driven Vision

Conventional machine vision systems depend on hard-coded rules to make decisions. These systems are inflexible and require extensive reprogramming when conditions change. AI-driven vision introduces adaptability, allowing systems to learn from data and improve over time. This transition from deterministic to probabilistic approaches marks a significant leap in capability.

How AI Enhances Machine Vision

Object Detection and Classification

AI models can detect and classify multiple objects in a frame with high accuracy, even in cluttered or variable backgrounds. This is especially useful in dynamic environments such as assembly lines, where objects may vary in orientation, size, or lighting conditions.

Anomaly and Defect Detection

Deep learning algorithms can identify defects that were previously undetectable due to their subtlety or randomness. These models excel at detecting scratches, blemishes, or inconsistencies that don’t conform to pre-defined rules, improving quality assurance.

Pattern Recognition in Complex Environments

AI excels at recognizing patterns and structures in noisy or unstructured visual data. It can differentiate between relevant and irrelevant features, which is critical for applications like surface inspection, facial recognition, or scene understanding.

Real-Time Decision Making

With AI, systems can process visual inputs and make decisions almost instantaneously. This allows for faster responses in applications like robotic control, autonomous navigation, or emergency system alerts.

Adaptive Learning

AI systems can be trained to handle new tasks or environments without reprogramming, making them highly scalable. They can also continuously learn from new data, adapting to variations and improving their performance over time.

Key Technologies Behind AI in Machine Vision

Deep Learning & CNNs

These are the backbone of modern AI vision, enabling sophisticated image recognition and classification. Convolutional Neural Networks (CNNs), in particular, are designed to automatically and adaptively learn spatial hierarchies of features from input images. This makes them highly effective for tasks such as detecting patterns, identifying objects, and classifying scenes—capabilities that are critical for machine vision applications in dynamic and complex environments.

Edge AI

Processing data directly on devices reduces latency and dependence on cloud infrastructure. Edge AI enables real-time decision-making by minimizing the time data needs to travel between the source and central servers. This is especially beneficial in time-sensitive environments like autonomous vehicles and industrial robotics.

Vision Transformers

A new class of neural networks providing high performance in vision tasks. Unlike traditional CNNs, vision transformers process image data using self-attention mechanisms, which can better capture global relationships in an image. They are increasingly used in tasks like image classification, segmentation, and object tracking.

Integration with IoT

Combining vision with sensors and cloud platforms enhances data richness and system responsiveness. This integration allows for synchronized data flows between machine vision systems and other industrial equipment, facilitating predictive maintenance, real-time alerts, and comprehensive process optimization.

Real-World Applications

The following industries illustrate how AI-powered machine vision is being applied in practice:

Manufacturing

AI vision identifies surface defects (e.g., scratches, dents), verifies assembly accuracy, and enables vision-guided robots to make dynamic adjustments during production.

Agriculture

Used for sorting produce by size, color, and ripeness, detecting plant diseases and pest infestations, and monitoring crop fields using drones for better yield management.

Logistics

Automates barcode scanning, package sorting, and conveyor tracking. Enhances real-time inventory management, mislabel detection, and warehouse routing optimization.

Healthcare

Supports diagnostics through medical imaging (X-rays, MRIs), detects anomalies like tumors, and assists in surgical guidance, patient monitoring, and lab automation.

Automotive

Ensures quality control by inspecting welds and finishes. Powers ADAS features like lane detection and collision avoidance, improving both manufacturing and on-road safety.

Benefits of AI in Machine Vision

AI brings a host of transformative benefits to machine vision systems, significantly enhancing their efficiency, adaptability, and reliability in industrial and commercial environments.

- Increased Accuracy and Speed: AI algorithms can process large volumes of visual data in real-time, significantly outperforming traditional systems in both speed and precision. This is particularly valuable in high-throughput environments like manufacturing lines or logistics centers.

- Reduced False Positives and Negatives: AI models can learn from vast datasets and refine their decision-making processes over time. This reduces the occurrence of false alarms or missed defects, improving the consistency and dependability of inspection results.

- Continuous Learning and Improvement: Unlike static rule-based systems, AI-powered solutions can continuously evolve through retraining. They adapt to new defect patterns, product designs, or operational changes without needing to be reprogrammed from scratch.

- Cost Efficiency and Operational Scalability: Though initial setup may be resource-intensive, AI systems often lead to substantial cost savings over time. These systems reduce the need for manual inspection, minimize downtime due to quality issues, and scale easily with increased production volumes.

- Improved Decision Support: AI systems can provide rich analytics and actionable insights, helping operators and managers make informed decisions quickly based on real-time visual data.

Challenges and Considerations

Data Requirements

Training AI models requires large, high-quality annotated datasets. Creating and labeling these datasets can be time-consuming and expensive, particularly for niche or specialized applications.

Computational Demands

AI models need powerful hardware for training and sometimes for inference. This can increase the cost and complexity of deploying machine vision systems, especially in environments with limited IT infrastructure.

Black-Box Nature

Lack of transparency in decision-making can be a barrier in critical applications. Understanding how and why an AI model arrived at a particular decision is crucial in sectors like healthcare, finance, or safety-critical manufacturing.

System Integration

Incorporating AI into existing workflows can be complex. It often requires re-engineering legacy systems, staff training, and ensuring compatibility with other software and hardware components.

Future Trends

Several trends are shaping the future of AI in machine vision. Self-learning systems that adapt to new data with minimal human input are becoming more common. Explainable AI (XAI) is improving the transparency of AI decisions, which is especially valuable in regulated industries. Edge computing is also on the rise, enabling real-time processing directly on devices. Lastly, falling costs and user-friendly tools are driving wider adoption among small and medium enterprises.

Conclusion

AI is redefining the capabilities of machine vision systems. By enabling greater flexibility, accuracy, and autonomy, it’s opening new possibilities in automation and quality control. Businesses that adopt AI-enhanced vision systems stand to gain a significant competitive edge as the technology continues to mature.