Industrial High-Speed Cameras: Key Technologies, Interfaces, and Applications

In the world of industrial automation, quality control, and scientific research, seeing what the naked eye can’t is often the key to precision and progress. That’s where high-speed cameras come in. These powerful imaging tools are designed to capture thousands of frames per second, revealing split-second events in stunning detail.

But not all high-speed cameras are created equal, and not every interface can handle the data they generate. This article explores what makes a camera high-speed, the interfaces that power them, and how technologies like GigE Vision fit into the picture.

What Makes a Camera ‘High-Speed’?

A high-speed camera is typically defined by its ability to capture hundreds or even thousands of frames per second (fps). But frame rate alone doesn’t tell the whole story. Here are the core components that determine a camera’s high-speed capabilities:

1. Frame Rate

Entry-level high-speed cameras may start around 250 fps, while advanced models can exceed 1,000,000 fps.

2. Shutter Speed

To freeze motion without blur, exposure times often need to be in the microsecond range. High speed cameras have short exposure mode to support the frame rate

3. Sensor Performance

High-speed imaging relies on fast readout sensors, usually CMOS, which can rapidly transfer pixel data to memory.

4. Onboard Buffering

Internal RAM stores frames temporarily before transfer, preventing data loss during capture.

5. Resolution vs Speed Trade-Off

Higher frame rates often require compromises on resolution. A camera might capture at 1,000 fps at 640×480, but only 200 fps at 1920×1080.

Interface Technologies for High-Speed Cameras

The interface is how your camera communicates with your computer, and it can make or break performance. High-speed cameras produce massive data streams, and the right interface ensures smooth, uninterrupted transfer.

Here’s an overview of common interfaces used in high-speed imaging:

GigE Vision

Based on standard Ethernet, GigE offers up to 1 Gbps bandwidth and cable lengths up to 100 meters. It’s ideal for moderate-speed applications (under 150–200 fps) and supports plug-and-play operation.

USB 3.0 / 3.1

Offers higher bandwidth (~5 Gbps), but is limited to short cable lengths (around 5 meters). Excellent for lab setups.

CoaXPress

One of the fastest interfaces available (up to 50 Gbps), ideal for ultra-high-speed imaging like crash testing or fluid dynamics.

Camera Link / Camera Link HS

Legacy high-speed interface is still used in many industrial setups. Requires an additional frame grabber as hardware, adding cost and complexity.

10GigE / 25GigE / 50GigE or 100GigE

Next-gen Ethernet options that extend GigE Vision into high-performance territory, supporting faster frame rates with longer cable lengths. These interfaces allows 10x, 25x, 50x or 100x GB of data transfer per second

Is GigE Fast Enough for High-Speed Imaging?

GigE Vision remains one of the most popular interfaces in machine vision, especially for systems that don’t demand extreme speed. Its strengths include:

- Affordable Infrastructure: Uses standard Cat6/Cat7 cables and doesn’t require a frame grabber.

- Long Cable Runs: Up to 100 meters without signal loss.

- Stable Bandwidth: Delivers consistent performance for cameras operating under 150 fps at 1MP resolution.

Bandwidth supported PCIE cards can be used to capture full bandwidth without packet loss

However, for applications demanding ultra-high frame rates or uncompressed high-resolution video, GigE may fall short. That’s where 10GigE or CoaXPress offer more headroom.

Applications of Industrial High-Speed Cameras

High-speed cameras are used in a wide range of industries and research fields. Some of the most common applications include:

1) Manufacturing & Quality Control

- Detecting defects on high-speed production lines.

- Monitoring robotic assembly or welding processes.

- Vibration analysis on heavy machinery

2) Automotive & Aerospace

- Crash testing and airbag deployment analysis.

- Fluid and combustion analysis in engines.

3) Electronics & Semiconductors

- Analyzing high-speed PCB placement machines.

- Verifying soldering quality in SMT lines.

4) Scientific Research

- Studying fast phenomena in physics, chemistry, and biology.

- Capturing projectile motion or vibration modes.

5) Pharmaceutical & Packaging

- Verifying fill levels in vials or bottles.

- Monitoring high-speed sorting and labeling operations.

In many of these fields, GigE Vision cameras are commonly used due to their versatility and ease of integration, especially when the required speed is moderate.

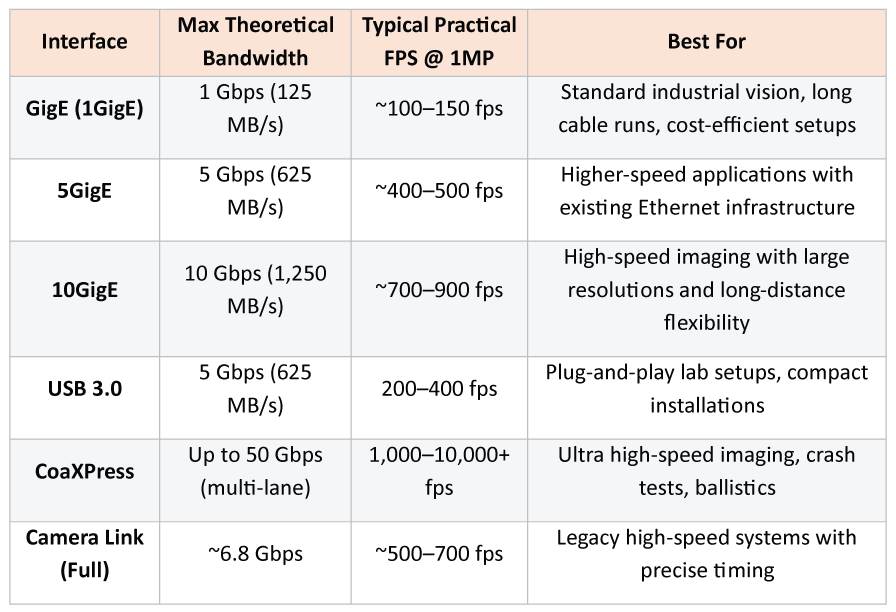

Interface vs Use Case: A Quick Comparison

Here’s a snapshot of how various interfaces compare in real-world scenarios:

Choosing the Right High-Speed Camera

Before choosing a high-speed camera, ask these questions:

- What frame rate and resolution do you need?

- Do you need real-time streaming, or is buffered capture acceptable?

- What interface does your system support?

- What are the environmental constraints (e.g., heat, dust, vibration)?

- What’s your budget for camera, software, and interface infrastructure?

GigE Vision cameras are often a sweet spot, balancing speed, affordability, and ease of integration. For tasks requiring extreme speed or ultra-high resolution, moving to a higher-bandwidth interface may be necessary.

Conclusion

Industrial high-speed cameras are transforming how manufacturers, researchers, and engineers observe the invisible. While frame rate and sensor speed are crucial, don’t overlook the importance of the interface that connects your camera to the rest of your system.

GigE Vision stands out as a reliable, cost-effective option for many high-speed applications, but it has its limits. For moderate-speed needs, it offers exceptional value. For cutting-edge speed and detail, explore higher-bandwidth interfaces like CoaXPress or 10GigE.

The key is to match the right camera and interface to your specific imaging challenge.