Enter your details below to download the product catalogue.

With polarization cameras, capturing detailed surface characteristics and material properties has become more efficient, offering industries a powerful tool for advanced inspection and analysis. These cameras provide critical insights by detecting light polarization, making them invaluable for applications such as stress analysis, glare reduction, and surface inspection. From industrial automation to biomedical imaging, the versatility of polarization cameras continues to drive innovation. Discover cutting-edge industrial polarization cameras in India with us.

Featuring an innovative 4 pixel block design with 4 unique angled polarizers, Sony is taking polarized imaging to the next level with 2/3 global shutter sensors.

The polarizer array is comprised of four different angled polarizers (90°, 45°, 135° and 0°) which are placed on each pixel.

With in-built polarization, there are no moving parts with no flipping, no time delay between polarizers, and overall system cost saving.

GigE Vision compliant for maximum 3rd party software compatibility. The Power Over Ethernet (PoE) port simplifies power and data over one cable.

The super compact design of the Phoenix camera (24 x 24mm) and (28 x 28 mm) enables OEMs to adapt to diverse product developments.

The IP67 offers protection from Dust, Dirt and Water ensuring long-term camera durability in harsh industry conditions. Lucid also offers IP67 Lens Tube.

Polarization cameras play a crucial role in a variety of industries by offering enhanced imaging capabilities that go beyond conventional vision systems. They are particularly effective in plastic shrink wrap inspection, enabling the detection of stress patterns and inconsistencies that are otherwise invisible to standard cameras. In metal and reflective surface inspection, polarization technology helps reduce glare and enhance defect detection, ensuring superior quality control. These cameras are also widely used for transparent material analysis, providing critical insights into surface properties and structural integrity.

Additionally, their ability to operate efficiently in low-light conditions makes them ideal for applications where standard imaging systems fall short. Another key application is 3D structure inspection, where polarization imaging helps capture intricate surface details and improve depth perception for more accurate assessments. Whether in manufacturing, quality control, or advanced research, polarization cameras offer unparalleled precision and reliability across diverse industrial applications.

Product Name

Product Name

Product Name

Product Name

Product Name

Product Name

Product Name

For color 3D imaging. The cameras are dust-proof and water-resistant.

Built for outdoor purposes, delivers the best quality images even in full sunlight.

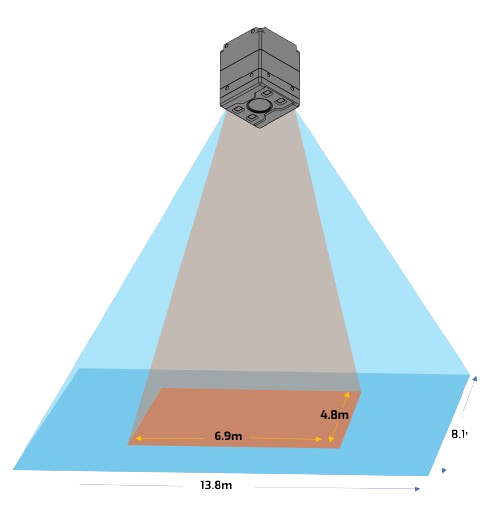

For applications with close working distances and large operation areas.

| Models | MP | Resolution | FPS | Sensor | Sensor Size | Pixel Size | Shutter | Lens Mount | Chroma | GigE Interface |

|---|---|---|---|---|---|---|---|---|---|---|

| TRI050S1-P/Q | 5.0 MP | 2448 x 2048 px | 22 fps | Sony IMX264MZR / MYR CMOS | 2/3" | 3.45 µm | Global | C | Polarized Mono/Color | M12 GigE Vision |

| TRI050S-P/Q | 5.0 MP | 2448 x 2048 px | 22 fps | Sony IMX250MZR/MYR CMOS | 2/3" | 3.45 µm | Global | C | Polarized Mono/Color | M12 GigE Vision |

| PHX050S1-P/Q | 5.0 MP | 2448 x 2048 px | 22 fps | Sony IMX264MZR/MYR CMOS | 2/3" | 3.45 µm | Global | C / C Ext Head / NF / NM | Polarized Mono/Color | RJ45 / ix Connector / FFC |

| PHX050S-P/Q | 5.0 MP | 2448 x 2048 px | 22 fps | Sony IMX250MZR/MYR CMOS | 2/3" | 3.45 µm | Global | C / C Ext Head / NF / NM | Polarized Mono/Color | RJ45 / ix Connector / FFC |

Discover the ideal machine vision camera for your specific needs, with solutions tailored to your application and budget. Get expert guidance and pricing today.

Enter your details below to download the product catalogue.