SWIR Cameras: What Are They? [Imaging & Application Guide]

Short-Wave Infrared (SWIR) imaging opens a window into parts of the light spectrum that are invisible to the human eye. SWIR cameras capture wavelengths typically ranging from 900 to 1700 nanometers, revealing critical insights in industrial inspection, agriculture, defence, and scientific research. As machine vision continues to evolve, SWIR technology is emerging as a powerful solution for advanced imaging challenges.

What Are SWIR Cameras?

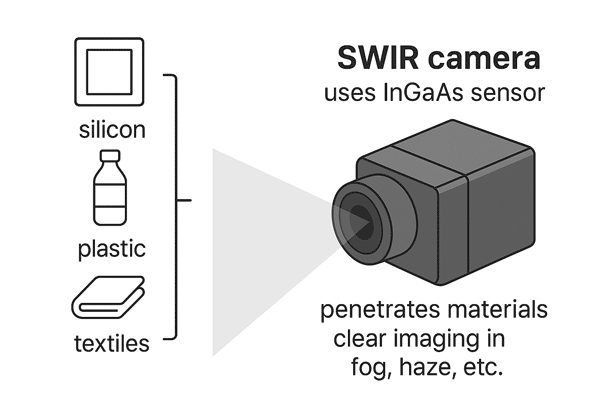

SWIR cameras operate in the short-wave infrared band of the electromagnetic spectrum. Unlike visible light or even long-wave infrared (LWIR), SWIR imaging can penetrate certain materials like silicon, plastic, and textiles, making it ideal for applications where visual inspection is limited. These cameras often use sensors made from Indium Gallium Arsenide (InGaAs), which are highly sensitive in the SWIR range. This unique sensitivity enables clear imaging in low-light or challenging atmospheric conditions such as fog, haze, or smoke.

Key Features of SWIR Cameras

Material Penetration

SWIR cameras have the ability to see through packaging materials, surface coatings, and even silicon wafers. This makes them essential in electronics manufacturing, pharmaceutical packaging inspection, and non-destructive testing environments where traditional imaging falls short.

Low-Light Performance

These cameras perform exceptionally well in environments with limited ambient light. Their high sensitivity in the 900–1700 nm range allows for clear, sharp imaging in dark, foggy, or smoky conditions, making them ideal for both industrial and surveillance use.

Resolution and Frame Rates

SWIR cameras are available in various resolutions ranging from 1.3 MP to over 5 MP. They also offer high frame rates suitable for high-speed imaging tasks, such as monitoring fast-moving production lines or dynamic laboratory experiments.

For instance, the Triton2 SWIR 5.2MP camera, equipped with the Sony IMX992 InGaAs sensor, delivers a maximum frame rate of 49.4 frames per second (FPS) at full resolution (2560 x 2048 pixels) across 8, 10, and 12-bit ADC modes. This performance is facilitated by its 2.5GigE interface, providing a bandwidth of 300 MB/s, making it ideal for high-speed imaging applications.

Such high-resolution and high-frame-rate capabilities are crucial for applications like semiconductor inspection, where capturing minute details at rapid speeds is essential, or in dynamic laboratory experiments that require precise temporal resolution.

Cooling Options

To reduce image noise and improve sensitivity, SWIR cameras come with different cooling configurations. Uncooled models are suitable for general use, while thermoelectrically cooled (TEC) variants are better for precision applications requiring long exposure times or consistent performance over extended periods.

Interface Options

Integration into existing systems is seamless with SWIR cameras, thanks to standard interfaces such as GigE Vision, USB3 Vision, and Camera Link. Notably, 2.5GigE Vision cameras are now emerging, offering enhanced bandwidth (up to 300 MB/s). This allows higher frame rates even at high resolutions, making them ideal for demanding applications like high-speed inspection and scientific imaging.

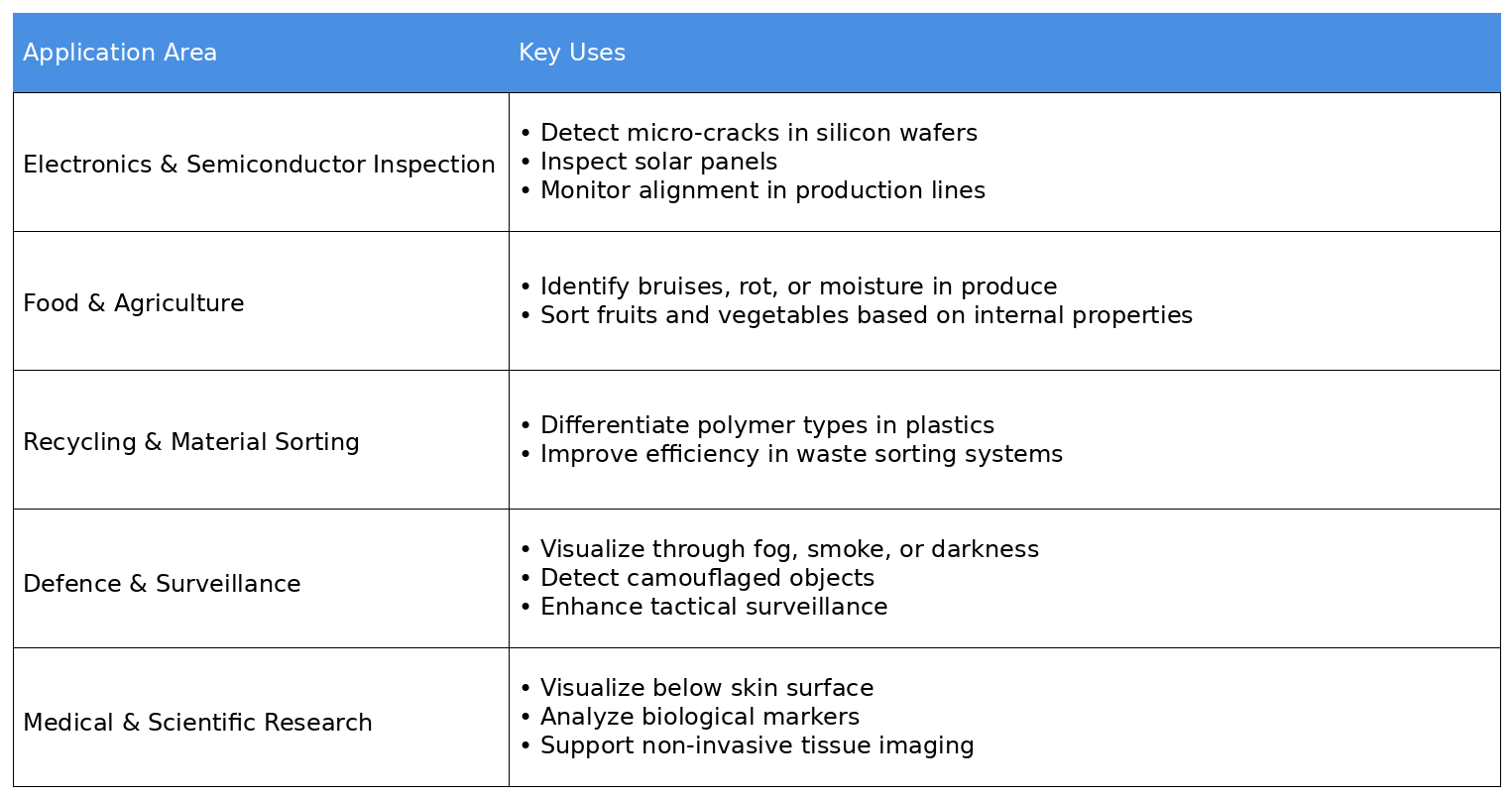

Applications of SWIR Cameras

Electronics and Semiconductor Inspection

SWIR imaging is invaluable in detecting defects in silicon wafers, inspecting solar panels, and monitoring manufacturing lines for micro-cracks or alignment issues that are invisible in visible light.

Food and Agriculture

In agricultural sorting and food inspection, SWIR cameras detect bruises, rot, or moisture content in produce. These qualities are often undetectable by traditional cameras but critical for ensuring quality and reducing waste.

Recycling and Material Sorting

Material differentiation, especially in plastic recycling, becomes more accurate with SWIR imaging. It helps identify different types of polymers based on their spectral signatures, improving recycling efficiency.

Defence and Surveillance

SWIR cameras provide enhanced imaging in low-light or obscured environments, such as through fog or smoke. They can detect objects that are camouflaged to the naked eye, making them valuable for surveillance, reconnaissance, and tactical operations.

Medical and Scientific Research

SWIR is also used in biomedical imaging to visualize beneath the skin’s surface, identify biological markers, and analyze tissue in non-invasive ways.

How to Choose the Right SWIR Camera

Selecting the right SWIR camera depends on several technical and operational factors that align with your application needs:

Resolution and Frame Rate

If your application involves high-precision inspection, opt for cameras with higher resolutions to capture finer details. For high-speed production lines or real-time monitoring, frame rate becomes more critical. Choose a camera that can handle the required frames per second without compromising image quality.

Cooling Needs

Cooling impacts image noise and overall performance. Uncooled cameras are cost-effective and sufficient for standard tasks, but for long exposure or thermally sensitive imaging, thermoelectrically cooled (TEC) models offer significantly reduced noise and enhanced image stability.

Spectral Range

Ensure the camera’s spectral sensitivity matches the target materials or conditions you intend to image. While many applications are effective within the standard 900–1700 nm SWIR band, some may require extended spectral coverage. LUCID’s SWIR cameras offer Visible + SWIR imaging, making them suitable for applications that require coverage across both the visible and SWIR spectrum using a single device—ideal for tasks that span multiple spectral ranges without needing multiple cameras.

Interface Requirements

Integration into existing setups is easier when the camera supports common interfaces like GigE Vision, USB3 Vision, or Camera Link. Confirm compatibility with your current imaging software and hardware to avoid bottlenecks in data transmission or integration.

Budget

SWIR cameras vary widely in price based on sensor type, resolution, cooling, and interface features. Consider your operational priorities—whether performance or affordability is more critical—and choose a model that aligns with your project scope.

Additionally, don’t overlook SWIR lighting, which is critical for capturing accurate images. A common mistake is using standard visible lighting, which does not emit in the SWIR spectrum, leading to poor or no image response. Always pair your camera with appropriate SWIR-compatible illumination for optimal performance.

Trends and Innovations in SWIR Technology

Recent advances in InGaAs sensor technology are significantly expanding the capabilities of SWIR cameras. These improvements have enabled wider spectral ranges, opening up new imaging possibilities across industries.

Artificial Intelligence (AI) integration is another major innovation, allowing SWIR cameras to perform real-time defect detection, classification, and pattern recognition. This reduces manual effort and increases accuracy in inspection and sorting tasks.

In addition, miniaturization of SWIR camera modules is making the technology more adaptable to compact and mobile systems. As costs continue to decrease, SWIR cameras are becoming more accessible not just for large industrial operations but also for small- and medium-sized enterprises seeking high-performance imaging solutions.

Conclusion

SWIR cameras are transforming how industries visualize the invisible. With applications ranging from semiconductor inspection to agricultural quality control and defence surveillance, they offer a powerful tool for precision imaging. As technology matures and becomes more accessible, SWIR cameras are set to play a pivotal role in next-generation machine vision systems.

Ready to explore SWIR cameras for your application? Reach out to us to find the right model for your needs.

Frequently Asked Questions

1. What are the different types of SWIR cameras available?

SWIR cameras can be categorized based on cooling (uncooled vs. TEC-cooled), interface type (GigE, USB3, Camera Link), resolution, and form factor. Some are designed for general industrial use, while others cater to scientific research, defence, or mobile platforms.

2. Can SWIR cameras see through walls or metals?

No, SWIR cameras cannot see through solid walls or metals. However, they can penetrate certain materials like silicon, plastics, and textiles, making them suitable for inspection tasks where surface layers need to be analyzed.

3. Are SWIR cameras safe for human use?

Yes, SWIR cameras are safe. They operate passively by detecting reflected light in the short-wave infrared spectrum and do not emit harmful radiation.

4. How does SWIR compare to thermal infrared imaging?

Thermal infrared (like LWIR) detects heat emitted by objects, whereas SWIR captures reflected light from external sources. SWIR offers higher image resolution and is more effective for imaging scenes with detailed texture or contrast under low-light conditions.

5. Do I need special lenses for SWIR cameras?

Yes. SWIR imaging requires lenses made from materials like fused silica or sapphire that transmit short-wave infrared wavelengths. Standard visible-light lenses block SWIR light and are unsuitable for this purpose.

6. Why is SWIR lighting important?

SWIR cameras rely on illumination in the short-wave infrared spectrum. Using visible light will not yield effective results. For optimal imaging, ensure your setup includes SWIR-compatible light sources tailored to your application.

7. What types of sensors are used in SWIR cameras?

Most SWIR cameras use InGaAs sensors for sensitivity in the 900–1700 nm range. At Hwyl, we offer models equipped with Sony IMX990, IMX991, IMX992, and IMX993 sensors—part of Sony’s latest generation of high-performance InGaAs sensors, providing superior resolution, noise control, and spectral range coverage.