Enter your details below to download the product catalogue.

Applications of High-Speed Cameras: From Industrial Testing to Cinematic Storytelling High-speed cameras have become essential tools across science, engineering, manufacturing, and even entertainment. By capturing events that happen in microseconds, they reveal details too fast for the human eye or conventional video equipment. Whether it is understanding how a product breaks during a drop test, analyzing complex fluid patterns, or producing cinematic slow motion for advertisements, high-speed imaging opens a window into hidden worlds. In this blog post, we explore the major applications of high-speed cameras across industries, with examples ranging from crash tests and ballistics to content creation and biomechanics. These use cases highlight how powerful high-speed imaging has become for innovation, problem solving, and storytelling. 1. Product and Material Testing One of the most common uses of high-speed cameras is in product and material testing. Understanding how materials behave under stress, impact, or motion helps engineers improve safety and durability. Drop Testing Companies conduct drop tests on everything from smartphones and appliances to packaging and protective gear. A high-speed camera captures the exact moment of impact and how shock waves travel through the product. Engineers can identify weak…

What Are High Speed Cameras: A Comprehensive Guide If you have ever wondered how filmmakers capture a bullet piercing glass, how engineers study car crash impacts, or how scientists analyse the motion of a hummingbird’s wings, the answer lies in high speed cameras. These specialized imaging systems record motion at thousands or even millions of frames per second, revealing details too fast for the human eye or a normal camera to detect. In this guide, we break down what high speed cameras are, how they work, and the key technologies that power them. What Is a High Speed Camera? A high speed camera is designed to capture video at extremely high frame rates far beyond the 24 to 60 fps recorded by most consumer or professional video cameras. Depending on the model, a high speed camera may capture anywhere from 1,000 fps to more than 1,000,000 fps. At these speeds, events that normally occur in an instant such as a droplet hitting a surface, an airbag deploying, or a manufacturing defect can be slowed down and analyzed in great detail. This makes high speed cameras indispensable in research, engineering, production,…

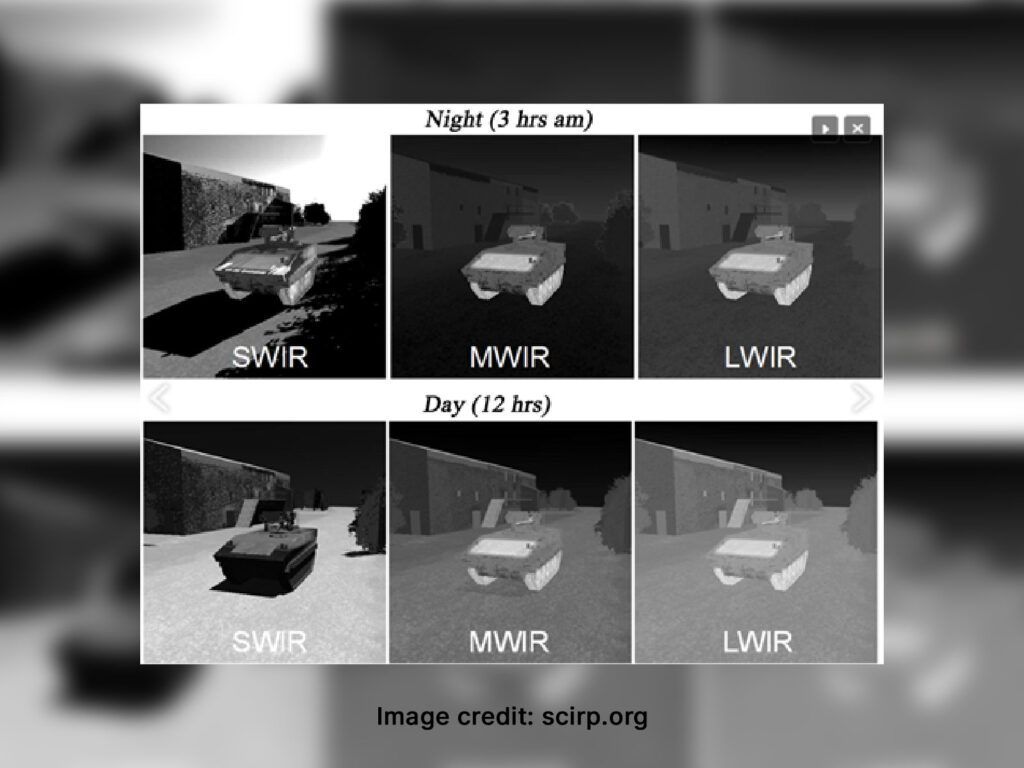

SWIR vs MWIR vs LWIR Cameras: Tech Specs Comparison & Applications Infrared imaging is now an essential part of modern machine vision, industrial monitoring, defence systems, and surveillance. But while most people refer to “thermal cameras” broadly, the reality is that infrared imaging spans multiple wavelength bands, each with different behaviours, advantages, and limitations. The three most widely used infrared categories are SWIR (Short-Wave Infrared), MWIR (Mid-Wave Infrared) and LWIR (Long-Wave Infrared). Understanding how these technologies differ can help you make the right choice for your project, whether it’s inspection, temperature measurement, environmental monitoring or security. Understanding the Infrared Spectrum Infrared light sits just beyond the visible spectrum, but it covers several atmospheric transmission windows. These windows influence how deeply each wavelength can penetrate fog, dust, glass, silicon or moisture. SWIR: 0.9 to 1.7 μm (sometimes up to 2.5 μm) MWIR: 3 to 5 μm LWIR: 8 to 14 μm Each region behaves differently. SWIR relies on reflective imaging similar to visible light. MWIR and LWIR detect emitted heat, but MWIR is more sensitive to fast temperature changes, while LWIR excels in general thermal detection. How Each Camera Type Works…

How to Select the Right LWIR Camera for Surveillance Applications Long-Wave Infrared (LWIR) cameras have become essential in modern surveillance because they detect heat instead of relying on visible light. Operating in the 8 to 14 µm range, they work in complete darkness and through challenging conditions such as fog, haze, smoke, and glare. Their passive operation makes them dependable for round-the-clock monitoring across industrial sites, borders, perimeters, and critical infrastructure. Selecting the right LWIR camera requires understanding several technical parameters, especially when the application demands reliable detection and identification. Understanding LWIR Technology LWIR cameras use uncooled microbolometer sensors that measure temperature differences in a scene and convert them into thermal images. Since all objects emit thermal radiation, LWIR cameras function independently of lighting conditions. This advantage makes them ideal for environments where visible cameras fail, such as at night, during storms, or in visually obstructed locations. LWIR imaging supports consistent surveillance across day and night cycles without reliance on artificial illumination. Evaluating Key LWIR Camera Specifications Selecting an LWIR camera requires evaluating its sensor attributes, sensitivity, image processing capabilities, and output interface. Each factor directly affects performance, clarity, and…

Industrial High-Speed Cameras: Key Technologies, Interfaces, and Applications In the world of industrial automation, quality control, and scientific research, seeing what the naked eye can’t is often the key to precision and progress. That’s where high-speed cameras come in. These powerful imaging tools are designed to capture thousands of frames per second, revealing split-second events in stunning detail. But not all high-speed cameras are created equal, and not every interface can handle the data they generate. This article explores what makes a camera high-speed, the interfaces that power them, and how technologies like GigE Vision fit into the picture. What Makes a Camera ‘High-Speed’? A high-speed camera is typically defined by its ability to capture hundreds or even thousands of frames per second (fps). But frame rate alone doesn’t tell the whole story. Here are the core components that determine a camera’s high-speed capabilities: 1. Frame Rate Entry-level high-speed cameras may start around 250 fps, while advanced models can exceed 1,000,000 fps. 2. Shutter Speed To freeze motion without blur, exposure times often need to be in the microsecond range. High speed cameras have short exposure mode to support the…

How to Choose the Right Weld Camera: A Buyer’s Guide for Industrial Applications In today’s fast-paced manufacturing and fabrication environments, weld cameras have become essential tools for improving weld quality, enhancing operator safety, and enabling process automation. From shipbuilding yards to robotic welding lines in automotive plants, choosing the right weld camera can directly impact productivity and inspection accuracy. But with so many options available, how do you determine which weld camera fits your specific needs? In this guide, we’ll walk you through the key factors to consider when selecting a weld camera and how to match the right model to your application. 1. Understand the Welding Process The first step in choosing a weld camera is identifying the type of welding process used in your operation. Different processes produce varying light intensities, smoke levels, and thermal signatures. MIG (Metal Inert Gas): Produces a bright arc and high spatter; requires high dynamic range (HDR) imaging. TIG (Tungsten Inert Gas): Cleaner process but still demands fine image clarity. Laser Welding: Needs precise focus and fast response due to high energy density. Submerged Arc or Plasma Arc: May need thermal or infrared…

SWIR Cameras: What Are They? [Imaging & Application Guide] Short-Wave Infrared (SWIR) imaging opens a window into parts of the light spectrum that are invisible to the human eye. SWIR cameras capture wavelengths typically ranging from 900 to 1700 nanometers, revealing critical insights in industrial inspection, agriculture, defence, and scientific research. As machine vision continues to evolve, SWIR technology is emerging as a powerful solution for advanced imaging challenges. What Are SWIR Cameras? SWIR cameras operate in the short-wave infrared band of the electromagnetic spectrum. Unlike visible light or even long-wave infrared (LWIR), SWIR imaging can penetrate certain materials like silicon, plastic, and textiles, making it ideal for applications where visual inspection is limited. These cameras often use sensors made from Indium Gallium Arsenide (InGaAs), which are highly sensitive in the SWIR range. This unique sensitivity enables clear imaging in low-light or challenging atmospheric conditions such as fog, haze, or smoke. Key Features of SWIR Cameras Material Penetration SWIR cameras have the ability to see through packaging materials, surface coatings, and even silicon wafers. This makes them essential in electronics manufacturing, pharmaceutical packaging inspection, and non-destructive testing environments where traditional…

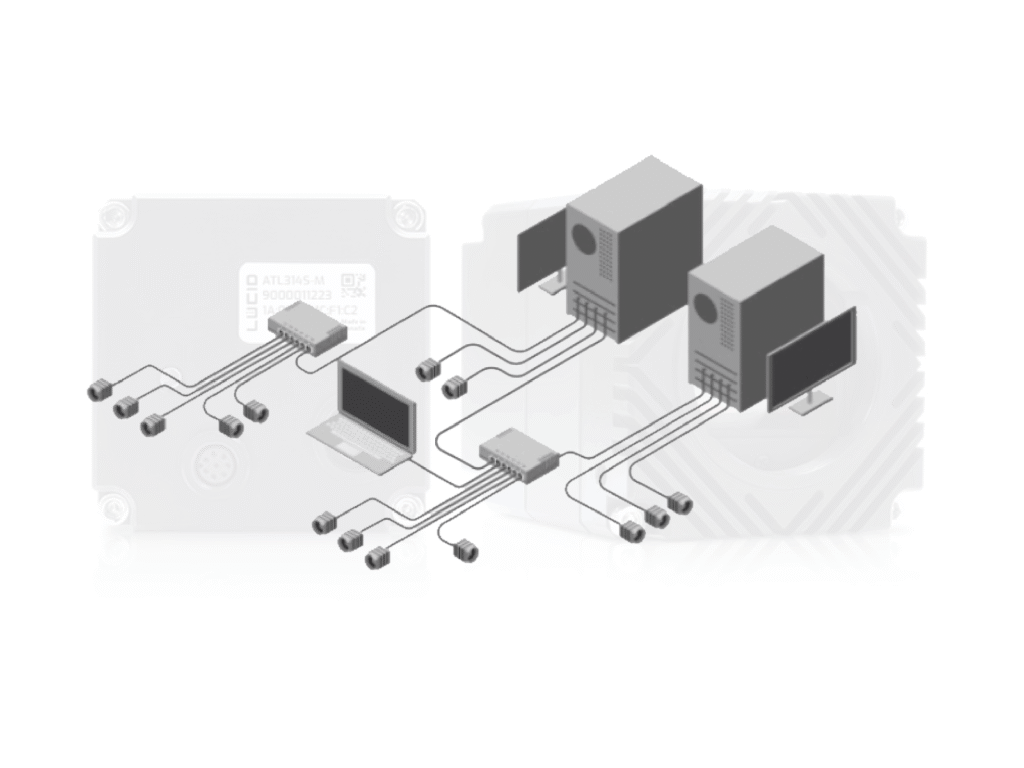

Understanding GigE Cameras: Interface, Advantages & Future Trends In the world of machine vision, choosing the right camera interface can make or break the efficiency of an imaging system. Whether you’re building a quality inspection solution for a manufacturing line or developing a vision-based AI model, the type of camera you select and how it connects to your system is critical. One interface that continues to stand out for its balance of performance, flexibility, and cost-effectiveness is GigE. In this post, we’ll dive into what GigE cameras are, how they compare to other popular interfaces like USB, CoaXPress, and Camera Link, and why they’re a great option for the future of high-speed, high-resolution imaging. What Are GigE Cameras? GigE cameras are industrial cameras that use Gigabit Ethernet (GigE) technology to transmit image data. GigE is a well-established networking standard (IEEE 802.3) capable of transferring data at up to 1 gigabit per second (1 Gbps) over standard Ethernet cables (CAT5e or CAT6). Unlike USB or Camera Link, GigE allows cameras to transmit data over long distances, up to 100 meters without the need for signal boosters or repeaters. These cameras are…

Time of Flight 3D Camera: What You Need to Know Time of Flight (ToF) technology has transformed depth sensing and 3D imaging by offering a fast, precise, and dependable method for measuring distances. ToF 3D cameras, which rely on this technology, are making significant contributions to 3D machine vision. They are driving advancements in areas like robotics, industrial automation, and consumer electronics. From robotic pick-and-place systems to autonomous navigation, these cameras have become essential in modern industries. What is a Time of Flight 3D Camera? A Time of Flight (ToF) 3D camera determines depth by calculating the time light takes to travel to an object and back—this is the core principle of Time of Flight. These cameras typically feature an infrared light source , a sensor to detect the returning light, and processors that convert the data into a 3D depth map or point cloud. Comparison with Other 3D Imaging Methods Stereo 3D This method utilizes two cameras positioned at slightly different angles to mimic human binocular vision, enabling depth calculation through the process of triangulation. While effective for capturing depth information, it requires precise alignment and intricate calibration to…