Enter your details below to download the product catalogue.

Weld Monitoring in Heavy Industries: Advancing Quality with Machine Vision In sectors like shipbuilding, aerospace, and infrastructure, welding forms the backbone of structural integrity. The quality of these welds directly impacts safety, durability, and regulatory compliance. Traditionally, industries have relied on post-weld inspection to detect flaws, but this approach can be reactive, costly, and sometimes too late. That’s where real-time weld monitoring comes in, enabling smarter, faster, and more accurate welding operations with the power of advanced machine vision. In this article, we explore how weld monitoring is transforming heavy industries, what welding methods are involved, and the role of technologies like HDR and SWIR imaging. Welding in Heavy Industries: A Sector-Wise Overview 1. Shipbuilding Welding is used extensively in constructing hulls, decks, and bulkheads. Techniques like Gas Metal Arc Welding (GMAW), Flux-Cored Arc Welding (FCAW), and Submerged Arc Welding (SAW) are common, especially for joining large steel components. Given the scale and complexity, weld consistency is crucial, making real-time monitoring essential for detecting irregularities early. 2. Aerospace Aircraft structures demand extremely precise welds, often involving Tungsten Inert Gas (TIG) and laser welding. Lightweight materials like titanium and aluminum alloys…

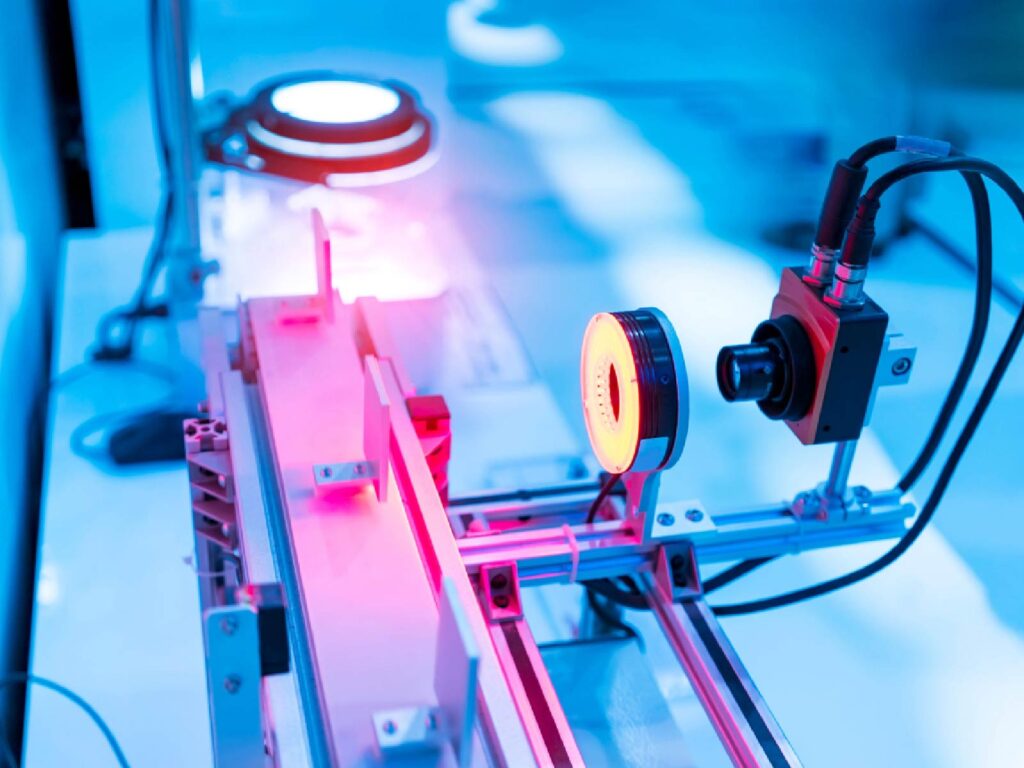

AI in Machine Vision: How It Is Transforming Industrial Vision Systems Machine vision, the technology enabling machines to interpret and act on visual data, has long been a cornerstone of industrial automation. Traditionally reliant on rule-based algorithms, machine vision systems were limited in their ability to handle complex or variable tasks. The integration of Artificial Intelligence (AI), particularly machine learning and deep learning, is now pushing the boundaries of what machine vision can achieve. This blog explores how AI is revolutionizing machine vision across industries. What Is Machine Vision? Machine vision involves the use of cameras, lighting, sensors, and software to capture and analyze visual information. In industrial settings, it’s used for inspection, measurement, object recognition, and robot guidance. Traditional systems function well in controlled environments but struggle with variations, anomalies, or complex decision-making tasks. The Evolution: From Rule-Based to AI-Driven Vision Conventional machine vision systems depend on hard-coded rules to make decisions. These systems are inflexible and require extensive reprogramming when conditions change. AI-driven vision introduces adaptability, allowing systems to learn from data and improve over time. This transition from deterministic to probabilistic approaches marks a significant leap in…

What is a Telecentric Lens? [A Comprehensive Guide] In high-precision imaging and machine vision applications, accuracy is everything. That’s where telecentric lenses come into the picture. Unlike standard lenses, telecentric lenses are designed to maintain consistent magnification and eliminate perspective errors, making them essential for industries where precise measurement and inspection are critical. In this post, we’ll break down what telecentricity means, how telecentric lenses work, their advantages, applications, and how you can choose the right one for your needs. What is Telecentricity? Telecentricity refers to a unique optical property where the chief rays (the main light rays from an object) are parallel to the optical axis of the lens. In simple terms, a telecentric lens ensures that the size of the image does not change even if the object moves closer to or farther away from the lens. In conventional lenses, objects closer to the lens appear larger, creating perspective distortion. Telecentric lenses eliminate this effect, making them ideal for measurement and quality inspection tasks where even the smallest deviations matter. How Does a Telecentric Lens Work? A telecentric lens is designed with special optical elements, often incorporating an…

SWIR Cameras: What Are They? [Imaging & Application Guide] Short-Wave Infrared (SWIR) imaging opens a window into parts of the light spectrum that are invisible to the human eye. SWIR cameras capture wavelengths typically ranging from 900 to 1700 nanometers, revealing critical insights in industrial inspection, agriculture, defence, and scientific research. As machine vision continues to evolve, SWIR technology is emerging as a powerful solution for advanced imaging challenges. What Are SWIR Cameras? SWIR cameras operate in the short-wave infrared band of the electromagnetic spectrum. Unlike visible light or even long-wave infrared (LWIR), SWIR imaging can penetrate certain materials like silicon, plastic, and textiles, making it ideal for applications where visual inspection is limited. These cameras often use sensors made from Indium Gallium Arsenide (InGaAs), which are highly sensitive in the SWIR range. This unique sensitivity enables clear imaging in low-light or challenging atmospheric conditions such as fog, haze, or smoke. Key Features of SWIR Cameras Material Penetration SWIR cameras have the ability to see through packaging materials, surface coatings, and even silicon wafers. This makes them essential in electronics manufacturing, pharmaceutical packaging inspection, and non-destructive testing environments where traditional…

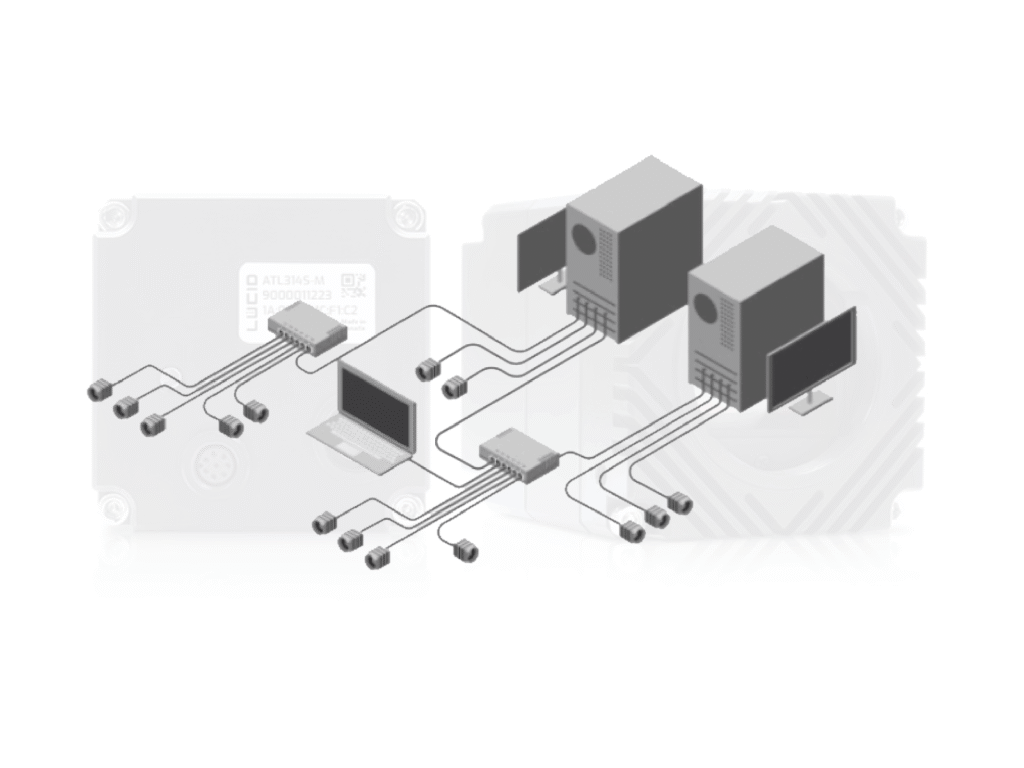

Understanding GigE Cameras: Interface, Advantages & Future Trends In the world of machine vision, choosing the right camera interface can make or break the efficiency of an imaging system. Whether you’re building a quality inspection solution for a manufacturing line or developing a vision-based AI model, the type of camera you select and how it connects to your system is critical. One interface that continues to stand out for its balance of performance, flexibility, and cost-effectiveness is GigE. In this post, we’ll dive into what GigE cameras are, how they compare to other popular interfaces like USB, CoaXPress, and Camera Link, and why they’re a great option for the future of high-speed, high-resolution imaging. What Are GigE Cameras? GigE cameras are industrial cameras that use Gigabit Ethernet (GigE) technology to transmit image data. GigE is a well-established networking standard (IEEE 802.3) capable of transferring data at up to 1 gigabit per second (1 Gbps) over standard Ethernet cables (CAT5e or CAT6). Unlike USB or Camera Link, GigE allows cameras to transmit data over long distances, up to 100 meters without the need for signal boosters or repeaters. These cameras are…

EO-IR Systems: A Game Changer in the Defence and Surveillance Space In today’s security and defence landscape, the ability to monitor, detect, and track potential threats with precision is more crucial than ever. Electro-Optical and Infrared (EO-IR) systems serve as the backbone of modern surveillance, providing unparalleled visibility across a range of environments and conditions. These advanced imaging systems are widely used in military operations, homeland security, and industrial monitoring to ensure continuous situational awareness. This article explores the fundamentals of EO-IR systems, various zoom options that enhance surveillance capabilities, the concept of Detection, Recognition, and Identification (DRI), and the overall impact of these technologies on defence and security applications. What Are EO-IR Systems? EO-IR systems are sophisticated imaging solutions that combine electro-optical (EO) and infrared (IR) sensors to capture real-time visuals in both visible and non-visible spectrums. These systems are essential for detecting objects in low-light, adverse weather, and high-security environments. Key Components of EO-IR Systems Electro-Optical (EO) Sensors EO sensors capture high-resolution images using visible light, functioning similarly to standard digital cameras. They are particularly effective in daylight operations, providing clear and detailed images for surveillance, reconnaissance, and…