The Role of Polarization Imaging in Machine Vision [2025]

In the world of machine vision, the demand for higher image clarity and more accurate defect detection is constantly growing. Industries rely on advanced imaging technologies to inspect products, detect flaws, and ensure quality control. One such innovation is polarization imaging, which has gained significant traction in recent years. By integrating the power of light polarization into machine vision systems, companies are able to see beyond the capabilities of traditional cameras. In this article, we will explore the role of polarization imaging in machine vision, its benefits, and how it is transforming industries in 2025.

What is Polarization Imaging?

To understand polarization imaging, we first need to grasp the concept of polarization in light. Polarization refers to the direction in which light waves oscillate. Most light from natural sources (like the sun) is unpolarized, meaning the light waves oscillate in all directions. However, when light interacts with surfaces or materials, some of it becomes polarized, causing the oscillations to align in a specific direction. Polarization imaging involves capturing these changes in light’s polarization to reveal valuable information that might be hidden in a standard image.

A key breakthrough in this area is Sony’s Polarsens™ technology, a specialized polarized sensor that incorporates four built-in polarizers within a compact CMOS sensor. This sensor can detect and filter light’s polarization angle, allowing for clearer and more detailed images. By filtering out unwanted glare and reflections, polarization imaging enhances contrast and reveals material properties that would otherwise be invisible to traditional sensors.

Benefits of Polarization Imaging in Machine Vision

1. Enhanced Image Clarity

One of the most significant benefits of polarization imaging is its ability to enhance image clarity. Traditional machine vision systems often struggle with glare and reflections, particularly when inspecting shiny, glossy, or transparent surfaces. By filtering out polarized light that causes reflections, polarization imaging ensures that the true surface details are visible. This is particularly useful in applications where high-quality imaging is essential, such as in quality control for automotive or electronics manufacturing.

2. Improved Contrast and Depth Perception

Polarization imaging also improves contrast in low-light or low-contrast environments. By emphasizing the polarization of light, this imaging technique can reveal subtle differences in surfaces that are difficult to discern with traditional sensors. In areas like material inspection, where the goal is to detect small imperfections or stress patterns, the increased contrast provided by polarization imaging can make all the difference. This improved contrast enhances the ability to detect even the smallest flaws that may affect product quality.

3. Material Property Analysis

Another compelling advantage of polarization imaging is its ability to reveal material properties. When light interacts with a material, it can reveal information about its texture, stress patterns, and even its composition. Polarization imaging allows machine vision systems to detect these properties, providing invaluable insights during inspections. For example, by analyzing how light is polarized on a surface, it’s possible to distinguish between different materials, or identify areas under mechanical stress, which could indicate potential failures or defects in products.

4. Advanced Surface Inspection

Surface inspection is one of the most common uses for machine vision, and polarization imaging takes it a step further. Standard cameras often miss subtle imperfections on surfaces, such as scratches, dents, or minor discolorations. Polarization cameras, however, can highlight these issues by detecting the way light is reflected from a surface. This is particularly useful in industries like automotive manufacturing, where surface defects can be critical to product quality. By using polarized light, manufacturers can identify flaws that would be invisible to the naked eye, leading to better quality assurance and fewer defects in the final product.

The Integration of Polarized Sensors in Machine Vision Systems

One of the key drivers of the adoption of polarization imaging is the integration of polarized sensors into machine vision systems. Sony’s Polarsens™ sensor is a prime example of how this technology is being used to revolutionize machine vision. Unlike traditional cameras, which use separate polarizers, Sony’s sensor integrates four unique polarizers within a single CMOS sensor, providing a more compact and efficient solution. These sensors can detect and filter polarized light directly, simplifying the imaging process and improving image quality in a variety of applications.

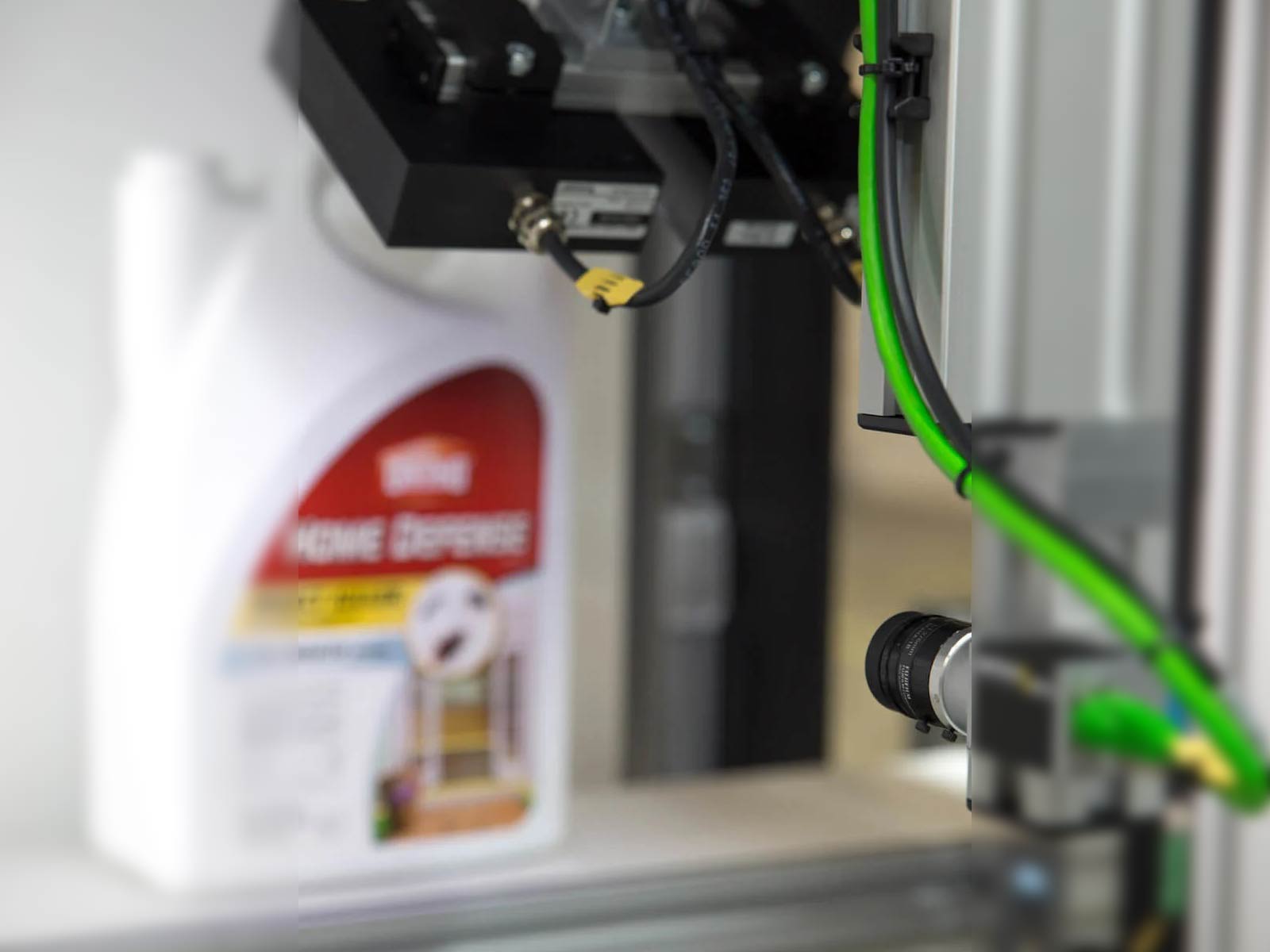

The integration of polarized sensors into machine vision systems allows for real-time analysis of polarized light, enabling more accurate inspections and faster decision-making. Cameras like the Phoenix and Triton, equipped with polarized sensors, are already being used in a wide range of industries to provide high-quality images that reveal important details in surface inspection, material analysis, and more.

Polarization Imaging: Applications in Different Industries

Polarization imaging is already making a significant impact across various industries. Some of the key sectors benefiting from this technology include:

1. Automotive Manufacturing

In the automotive industry, surface quality is critical. Polarization imaging allows manufacturers to inspect vehicle parts for defects like scratches, dents, or cracks that could affect performance or aesthetics. By using polarized light to examine surfaces, automotive manufacturers can ensure that every part meets the highest quality standards, improving both the safety and appearance of the final product.

2. Electronics

In electronics manufacturing, precision is paramount. Polarization imaging helps detect defects on delicate components like printed circuit boards (PCBs), which might be invisible under standard imaging techniques. By analyzing the polarization of light, manufacturers can identify subtle imperfections in the surface or material structure, ensuring that only the highest-quality parts are used in electronic devices.

3. Packaging and Labeling

Polarization imaging can also be used in packaging and labeling to inspect print quality, detect smudges, and ensure that labels are correctly applied. For products that require high-quality labeling or packaging, such as food, pharmaceuticals, and cosmetics, polarization imaging helps manufacturers maintain strict quality control standards. One specific application is inspecting plastic shrink wrap, which is commonly used to package products like instant noodles. Polarization imaging can detect surface damage, wrinkles, and foreign objects (like stickers) on the shrink wrap, ensuring that the packaging is flawless and visually appealing. This level of precision ensures the packaging looks professional and meets quality standards.

4. Agriculture

In agriculture, polarization imaging is being used to inspect crops and analyze soil conditions. By observing how light interacts with plants and the ground, polarization imaging can reveal subtle differences in vegetation health, moisture levels, and stress conditions. This information can be used to optimize crop management and improve yield predictions, offering a significant advantage for modern precision agriculture.

Looking Ahead: The Future of Polarization Imaging in Machine Vision (2025 and Beyond)

As machine vision technology continues to evolve, so too will the capabilities of polarization imaging. In 2025 and beyond, we can expect further advancements in sensor technology, enabling even more precise and efficient imaging. The integration of artificial intelligence (AI) and machine learning into these systems will also enhance the capabilities of polarization imaging, allowing for faster and more accurate analysis of visual data.

Moreover, polarization imaging is likely to be combined with other advanced imaging techniques, such as multi-spectral and hyperspectral imaging. These technologies, when integrated with polarization, can provide even more detailed and comprehensive information about the materials and surfaces being analyzed. As industries continue to demand greater precision and automation, polarization imaging will play a critical role in shaping the future of machine vision.

Conclusion

Polarization imaging is a powerful tool that is revolutionizing machine vision in 2025. With its ability to enhance image clarity, improve contrast, and reveal material properties, it is making significant contributions to industries like automotive, electronics, and agriculture. By integrating advanced polarized sensors such as Sony’s IMX 250 MZR/MYR and IMX 264 MZR/MYR, machine vision systems are becoming more efficient and capable of providing higher-quality results. These sensors, part of Sony’s Polarsens™ lineup, enable superior polarization sensitivity and image quality. As the technology continues to advance, polarization imaging will remain at the forefront of innovation, driving improvements in inspection, quality control, and automation across a wide range of industries.