Enter your details below to download the product catalogue.

Weld Monitoring in Heavy Industries: Advancing Quality with Machine Vision In sectors like shipbuilding, aerospace, and infrastructure, welding forms the backbone of structural integrity. The quality of these welds directly impacts safety, durability, and regulatory compliance. Traditionally, industries have relied on post-weld inspection to detect flaws, but this approach can be reactive, costly, and sometimes too late. That’s where real-time weld monitoring comes in, enabling smarter, faster, and more accurate welding operations with the power of advanced machine vision. In this article, we explore how weld monitoring is transforming heavy industries, what welding methods are involved, and the role of technologies like HDR and SWIR imaging. Welding in Heavy Industries: A Sector-Wise Overview 1. Shipbuilding Welding is used extensively in constructing hulls, decks, and bulkheads. Techniques like Gas Metal Arc Welding (GMAW), Flux-Cored Arc Welding (FCAW), and Submerged Arc Welding (SAW) are common, especially for joining large steel components. Given the scale and complexity, weld consistency is crucial, making real-time monitoring essential for detecting irregularities early. 2. Aerospace Aircraft structures demand extremely precise welds, often involving Tungsten Inert Gas (TIG) and laser welding. Lightweight materials like titanium and aluminum alloys…

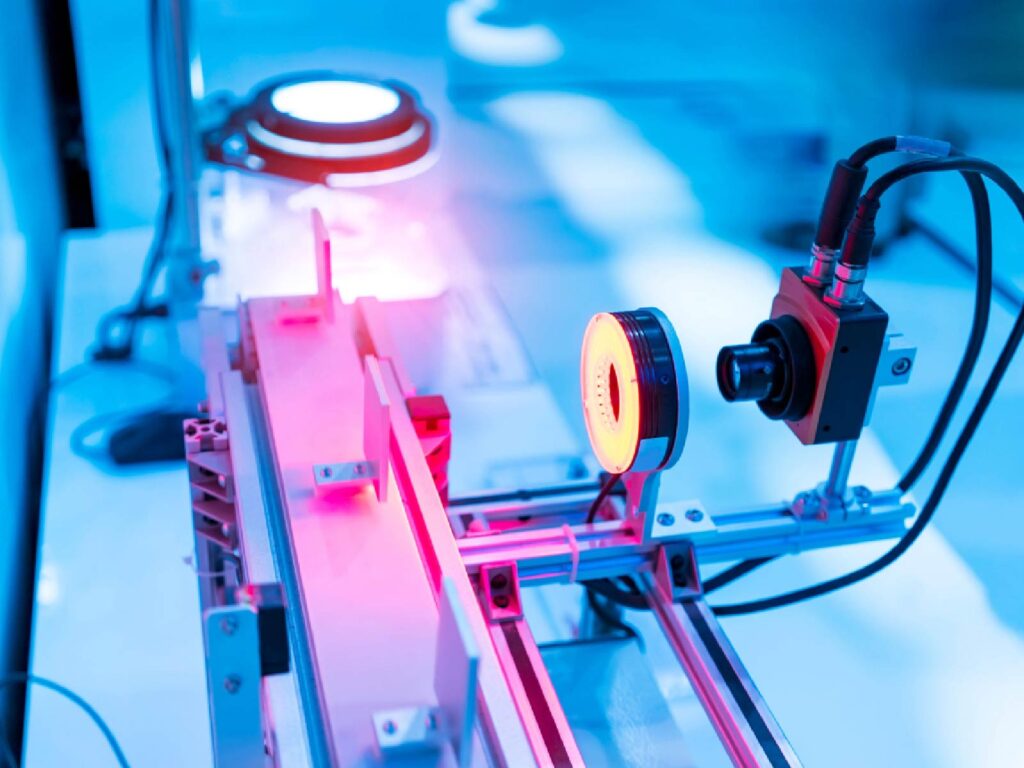

AI in Machine Vision: How It Is Transforming Industrial Vision Systems Machine vision, the technology enabling machines to interpret and act on visual data, has long been a cornerstone of industrial automation. Traditionally reliant on rule-based algorithms, machine vision systems were limited in their ability to handle complex or variable tasks. The integration of Artificial Intelligence (AI), particularly machine learning and deep learning, is now pushing the boundaries of what machine vision can achieve. This blog explores how AI is revolutionizing machine vision across industries. What Is Machine Vision? Machine vision involves the use of cameras, lighting, sensors, and software to capture and analyze visual information. In industrial settings, it’s used for inspection, measurement, object recognition, and robot guidance. Traditional systems function well in controlled environments but struggle with variations, anomalies, or complex decision-making tasks. The Evolution: From Rule-Based to AI-Driven Vision Conventional machine vision systems depend on hard-coded rules to make decisions. These systems are inflexible and require extensive reprogramming when conditions change. AI-driven vision introduces adaptability, allowing systems to learn from data and improve over time. This transition from deterministic to probabilistic approaches marks a significant leap in…

EO-IR Systems: A Game Changer in the Defence and Surveillance Space In today’s security and defence landscape, the ability to monitor, detect, and track potential threats with precision is more crucial than ever. Electro-Optical and Infrared (EO-IR) systems serve as the backbone of modern surveillance, providing unparalleled visibility across a range of environments and conditions. These advanced imaging systems are widely used in military operations, homeland security, and industrial monitoring to ensure continuous situational awareness. This article explores the fundamentals of EO-IR systems, various zoom options that enhance surveillance capabilities, the concept of Detection, Recognition, and Identification (DRI), and the overall impact of these technologies on defence and security applications. What Are EO-IR Systems? EO-IR systems are sophisticated imaging solutions that combine electro-optical (EO) and infrared (IR) sensors to capture real-time visuals in both visible and non-visible spectrums. These systems are essential for detecting objects in low-light, adverse weather, and high-security environments. Key Components of EO-IR Systems Electro-Optical (EO) Sensors EO sensors capture high-resolution images using visible light, functioning similarly to standard digital cameras. They are particularly effective in daylight operations, providing clear and detailed images for surveillance, reconnaissance, and…

5 Compelling Machine Vision Applications for a Sustainable India Sustainability has emerged as the need of the hour for countries across the globe. The Paris Agreement signed by 196 Parties, including India, aspires to limit global warming to below 1.5 degree celsius and attain net zero carbon emissions by 2050. This calls for countries world-over to pivot their development strategies towards smart sustainability. Machine vision, a subfield of computer vision, can help various sectors including agriculture, energy, transportation, waste management, environment and more, in this transformative journey by delivering smart solutions to sustainability issues. What is Machine Vision? Machine vision technology equips machines with “sight”. The set-up includes lighting, cameras with sensors, processors, and communication systems. Lighting illuminates the environment or object of focus, the lens and sensor within the camera captures images of the object and converts them into a digital format, and the processor extracts meaningful insights from the digital data through its built-in software and machine vision algorithms. Based on the data gathered by the processor, the system communicates with other machines, robots or software through output channels. Machine Vision System Applications in the Real World Smart…