The Ultimate Guide on Short Wave Infrared (SWIR)

While the human eye is an extraordinary creation that can perceive a vast spectrum of colors, there lies a wide spectrum of light beyond the visible range, waiting to be explored. The Infrared (IR) radiation extends beyond the visible spectrum of light (400 – 700 nm) and has a wavelength ranging from 700 – 1,000,000 nanometers (nm). This spectrum consists of four distinct wavebands such as the Near Infrared (NIR), Mid-Wave Infrared (MWIR), Short-Wave Infrared (SWIR), and Long-Wave Infrared (LWIR). While the NIR range is used for medical imaging and food inspection, LWIR finds its applications in thermal imaging and night vision.

SWIR imaging falls between NIR and LWIR, and it is typically used for high-resolution imaging in the visible and infrared spectrum. In this blog, we would be specifically examining SWIR in detail including its properties, benefits and what possibilities that lie ahead.

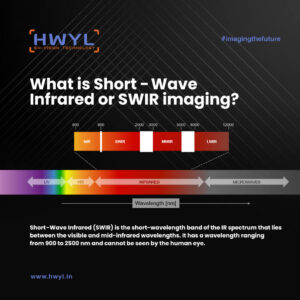

What is Short Wave Infrared or SWIR imaging?

SWIR is the short wavelength portion of the infrared spectrum and occupies the segment between the visible and mid-infrared wavelengths. It cannot be seen by the human eye or detected by conventional silicon-based cameras. It has a nominal wavelength ranging from 900 to 2500 nm. This range is apt for creating images of objects that have significant contrast between their surface and their surroundings. Since there are no fixed standards for each waveband, you may also come across classifications that denote SWIR as an extension of the NIR band.

Short Wave Infrared (SWIR) is the wavelength band that lies between the visible and mid-infrared wavelengths. It has a wavelength ranging from 900 to 2500 nm and cannot be seen by the human eye.

Over the years, Short Wave Infrared imaging has been put to use rampantly for various scientific, industrial, and commercial applications, due to its unique and diverse properties.

Properties of SWIR

Short Wave Infrared light interacts differently with materials as compared to visible light and long-wave infrared. Thus, it possesses a unique set of properties that make it a sought after imaging technology across industries:

- Reflective nature: Being highly reflective in nature, SWIR light bounces off objects creating shadows and contrast in imagery, just like the visible light.

- High penetration: On the other hand, SWIR can penetrate through haze, plastic, silicon, fog, smoke, glass and other materials that are opaque to visible light

- Sensitivity to water: SWIR light is highly sensitive to moisture content in materials and is strongly absorbed by water.

- High contrast and resolution: SWIR imaging produces high-contrast, high-resolution non-coloured images, making them a popular choice for applications that demand precision and clarity.

- Day and Night Vision Capability: The SWIR band has the capability to detect reflected light even in low-light conditions such as the night glow or night sky radiance. It can also be used for capturing images in daylight.

- Temperature Sensitivity: Due to its ability to detect temperature differences and variations, SWIR is ideal for thermal imaging applications.

- Material Differentiation: SWIR interacts differently with materials based on their composition, helping them differentiate between various substances within its range.

- Non-Destructive Imaging: SWIR imaging is non-destructive in nature and does not adversely affect the objects being inspected. This makes it ideal for monitoring sensitive environments and for conservation efforts.

Sensors Used in SWIR Technology

Different types of sensors, each with its own merits and demerits are used for SWIR imaging. Depending on the application, SWIR sensors can be adjusted to have linear or logarithmic response to avoid saturation.

Below are some of the commonly used SWIR sensors:

- Indium Gallium Arsenide (InGaAs) or Mercury Cadmium Telluride (MCT) sensors: InGaAs is the most popular sensor used in the SWIR range and offers a wide spectral range, high sensitivity and resolution. They are sensitive to wavelengths in the SWIR range and are perfect for defence, medical imaging and other applications. MCT is yet another option but is more expensive and application dependent. Popular InGaAs sensors are Sony IMX990 and Sony IMX991 SenSWIR sensors.

- Silicon (Si): Though less sensitive than InGaAs sensors, Si sensors are more affordable and are used for shorter SWIR wavelengths. Since traditional silicon-based sensors are limited to identifying wavelengths within the visible light range, specialized silicon sensors with additional are needed for identifying SWIR wavelengths.

- Lead sulfide (PbS): Lead sulfide sensors are highly affordable and sensitive and can be used for imaging between 1.4 to 3 micrometers – the longer wavelengths. However, they have a slow response time and also exhibit temperature sensitivity.

Applications of SWIR Imaging

SWIR imaging is used in a variety of applications across a diverse range of industries due to its unique properties and capabilities.Some of the popular ones include:

- Medical Imaging: SWIR imaging assists in non-invasive diagnostic techniques. It helps diagnose skin cancer, understand tissue composition, analyze wound healing, monitor blood flow and detect tissue composition.

- Silicon Wafer Inspection and Quality Control: Due to its ability to penetrate silicon materials, SWIR is widely used to detect defects in integrated circuits, thereby helping in achieving high standards of quality and reliability.

- Remote Sensing and Environmental Monitoring: SWIR is used to examine vegetation health, study soil composition and check moisture levels, thanks to SWIR wavelengths being sensitive to water . This helps take data-driven decisions regarding crop management, disease control and irrigation.

- Surveillance and Security: Enabling precise imaging and high penetration in low-light conditions, SWIR is employed in night vision surveillance, border security and perimeter monitoring. SWIR’s ability to penetrate through fog makes it ideal for surveillance in high altitude regions and is used in applications involving monitoring of take off and landing of the aircrafts.

- Food Inspection: Due to its molecular sensitivity, SWIR is used to identify bruising and defects in fruits, contamination in vegetables and other anomalies.

- Industrial Inspection: SWIR is used to identify cracks, foreign material, scratches and other defects in manufactured goods. It is also used to check the coating thickness in materials.

- Laser beam profiling: Another important application of SWIR is in laser beam profiling. It is used to measure and analyze laser-beam characteristics such as size, position, shape, propagation, and mode structure properties.

- Outdoor Imaging: A key advantage of SWIR band over visible light is that objects that have almost the same color in the visible region can be easily differentiated in the SWIR spectrum, making them easily recognizable. Since ambient star light and background radiance are some of the natural emitters of SWIR, it is apt for outdoor imaging.

SWIR also finds its applications in other fields such as art conservation and analysis, free space optical telecommunications (FSO), thermal imaging for manufacturing/agriculture, small animal imaging, astronomy, industrial sorting, laser beam profiling, solar cell inspection and more.

The Future of SWIR Imaging

There’s no doubt that SWIR imaging is growing at a rapid pace. Technological advancements and evolving product development are resulting in new and improved sensors, lenses, and lighting solutions entering the market like never before. This has led to the rampant adoption of SWIR technology across industries to enhance processes and improve efficiency with its unique capabilities. With ongoing research and development to unlock new possibilities in SWIR imaging, the technology is expected to leave a lasting impact on our day-to-day lives in the future.